Programmable Logic Controller (PLC)

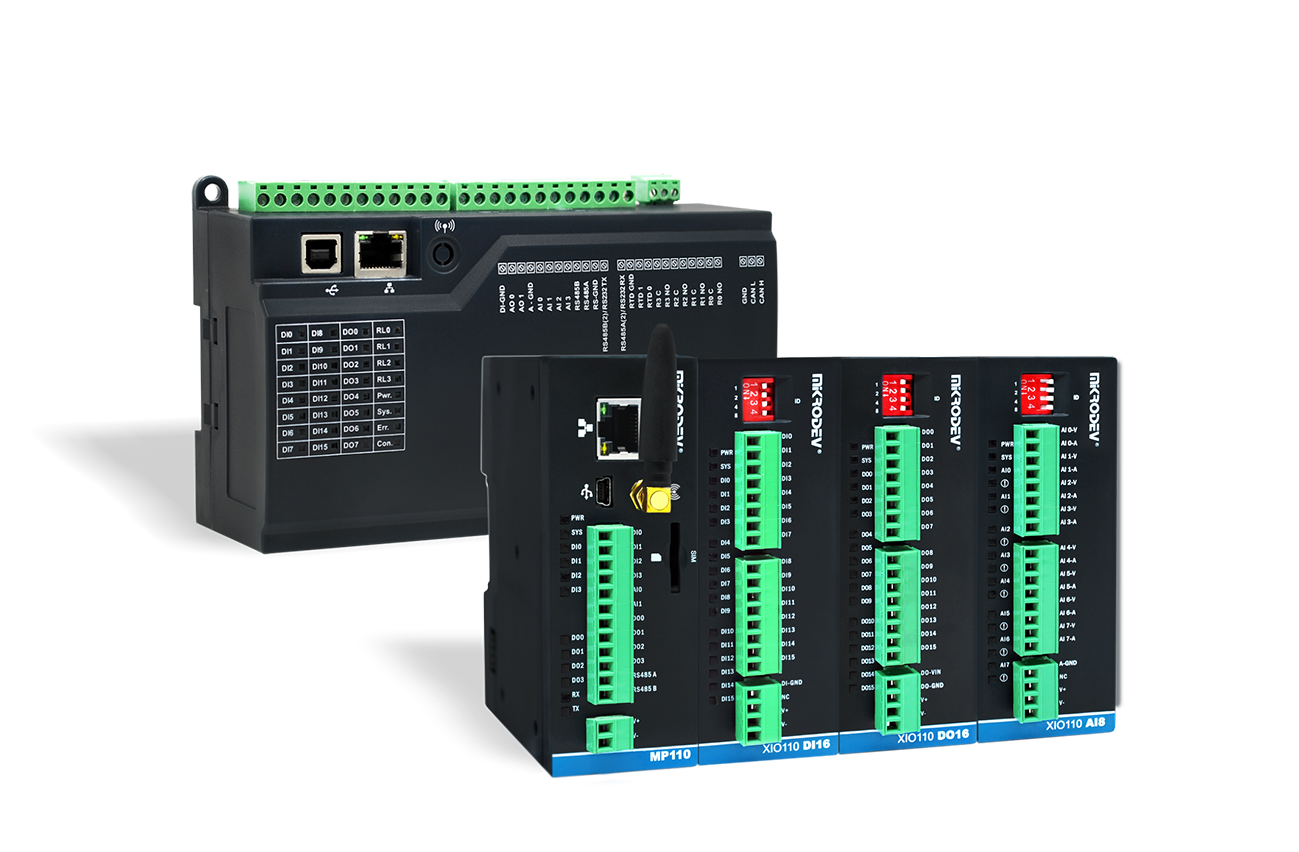

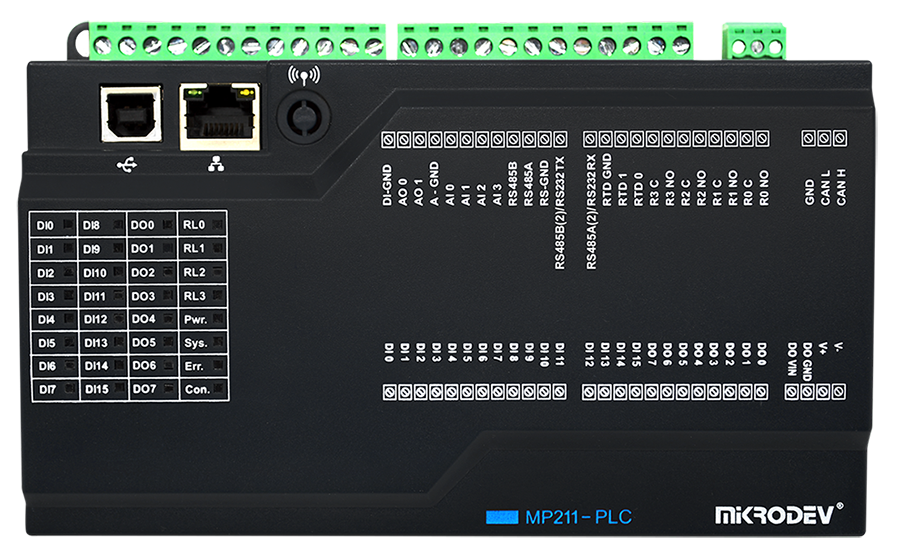

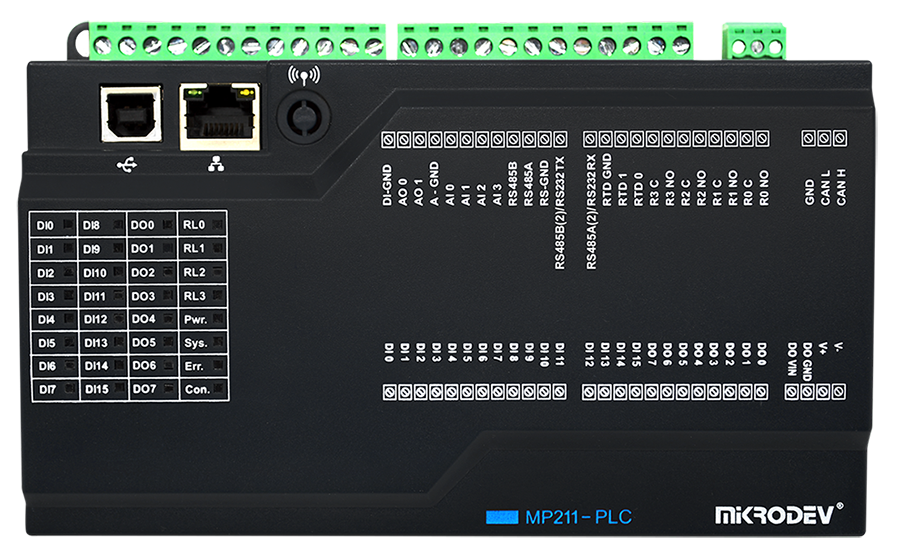

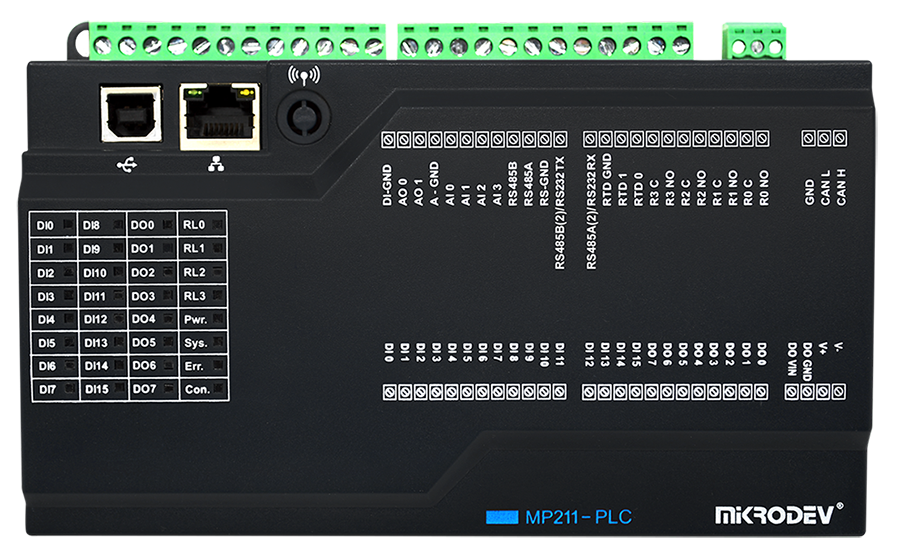

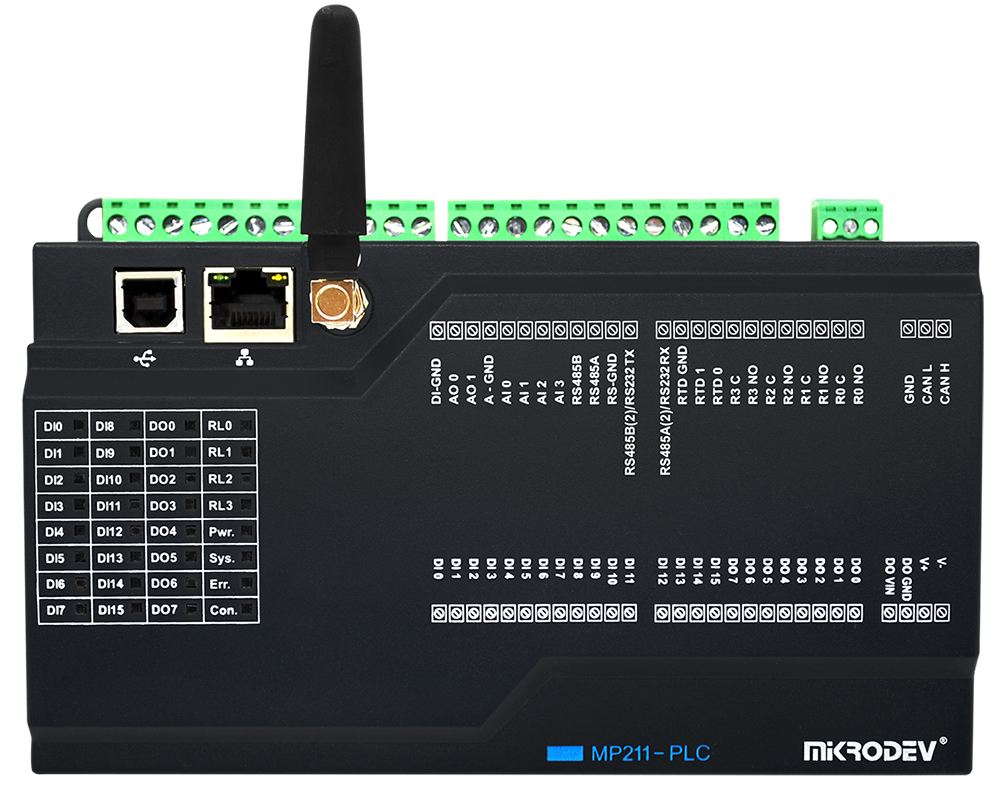

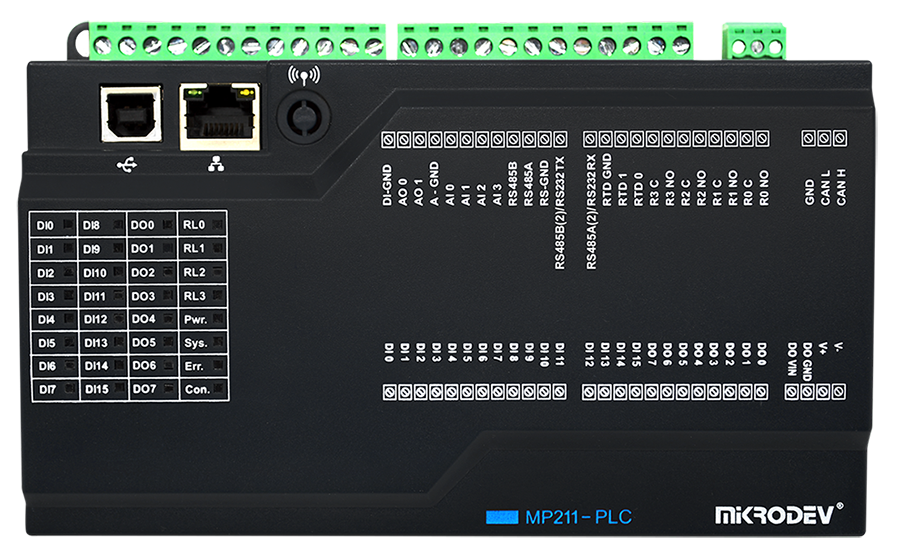

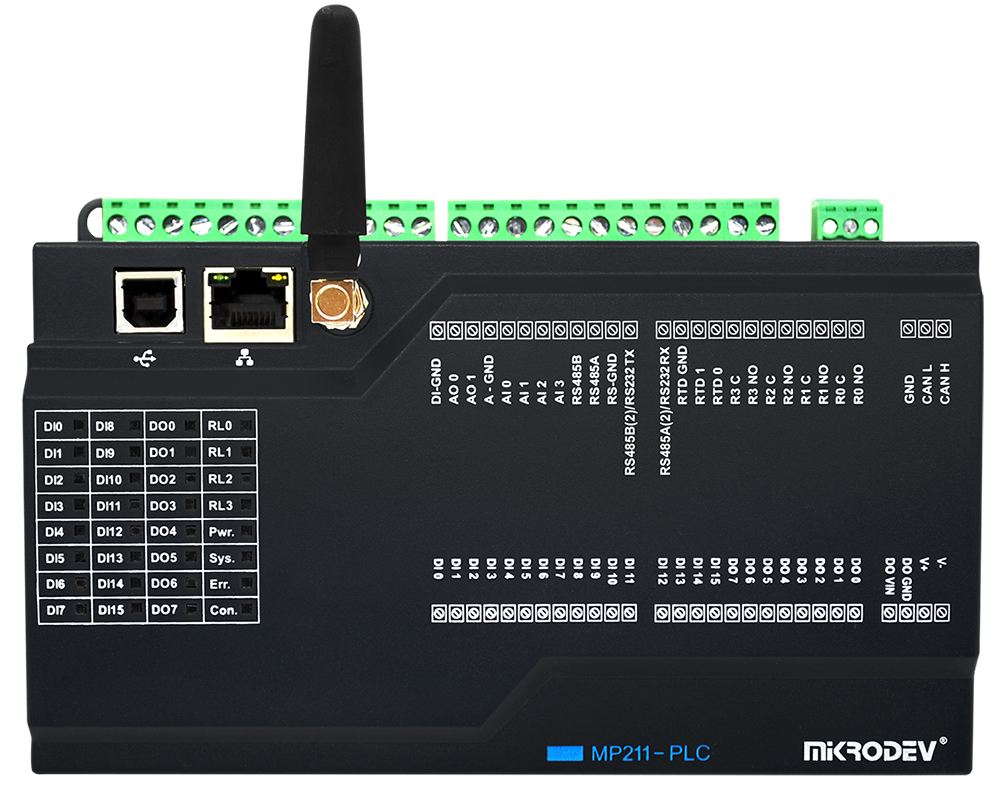

Mikrodev offers reliable solutions for industrial automation and IoT projects with programmable logic controllers (PLC) that comply with the IEC61131 standard. The modular MP110 series provides high flexibility, while the MP211 series, with its large I/O capacity, offers a compact and powerful solution for complex control applications.

Programmable Logic Controller (PLC) Systems

Programmable Logic Controller (PLC) systems are complex and integrated systems that have become

an essential component in industrial automation and robotics technologies. These advanced

systems are designed to monitor input signals, execute complex logical functions, and automate

and control various industrial processes through output signals. With their precision and

efficiency, PLC systems have transformed industrial operations and are now indispensable tools

in modern engineering.

PLC Devices and Mikrodev Solutions

Programmable Logic Controllers (PLC)

are electronic devices used to perform sequencing, timing, speed, and motion control operations

in industrial automation systems. These devices evaluate data according to predefined programs

and generate outputs accordingly. PLC systems are widely used for secure and reliable industrial

automation applications.

Mikrodev programmable logic controller devices provide solutions for a wide range of application

areas by supporting internationally recognized communication protocols such as Modbus RTU,

Modbus TCP, and IoT-oriented protocols like MQTT. As one of the leading PLC manufacturers,

Mikrodev continues to invest in advanced technologies to strengthen its position in the

industrial automation sector.

PLC GSM Technology and Remote Control

PLC GSM technology enables remote monitoring and control of systems via the Global System for

Mobile Communications (GSM) network. This integrated solution offered by Mikrodev allows

operators to manage facilities, devices, and systems located in remote areas without internet

infrastructure. For example, data from remote stations can be monitored and controlled from a

central location through telecommunication networks using PLC GSM technology.

PLC GSM-enabled devices within the Mikrodev product range make it possible to remotely control

and manage industrial automation systems more efficiently, improving operational continuity

and reducing maintenance costs.

Communication Interfaces and Protocol Support

Ethernet is provided as a standard communication port on Mikrodev PLC devices. Additionally,

optional GSM/2G-GPRS, GSM/4G-LTE, and Wi-Fi communication modules are available. PLC programming

with GSM support enables communication through GSM modems using 2G or 4G technologies, allowing

remote monitoring and control.

Mikrodev PLC systems support communication protocols such as MODBUS and MQTT, making them highly

suitable for internet-based and IoT applications. PLC devices can communicate with each other

over the Modbus protocol and integrate seamlessly with RTU units and SCADA software. In MQTT

communication, data can be published via brokers using time-based tags, and subscriptions can be

defined for specific data streams.

Environmental Compatibility and Application Areas

Mikrodev programmable logic controller devices are designed to operate reliably in harsh

environmental conditions, offering high compatibility across a temperature range of

-20°C to +60°C. All technical specifications can be accessed through individual product pages,

where advanced filtering options allow users to select devices based on specific requirements.

Mikrodev PLC products are widely used in various industrial automation fields, including

building automation, energy systems, water and wastewater management, process automation,

machine automation, transportation systems, IoT and telemetry applications, lighting systems,

and agricultural irrigation.

With these advanced capabilities, Mikrodev PLC devices stand out in industrial automation and

industrial control systems, offering complete and reliable solutions that enhance efficiency,

optimize resource usage, and deliver long-term operational savings.