In industrial or commercial IoT projects, IoT gateways play a crucial role in ensuring accurate and fast data flow between devices. An IoT gateway brings together different protocols, devices, and applications, enabling seamless data exchange. Choosing the right model based on features, performance criteria, protocol support, and device capacity directly impacts the success of the project. A reliable IoT gateway can manage hundreds of devices simultaneously and securely process data before transmitting it to the central system—enhancing both the reliability and efficiency of the entire network.

Core Features: What an IoT Gateway Should Offer

When selecting an IoT gateway, it’s essential to focus on the critical features behind technical specifications. A model that seems “sufficient” at the beginning of a project may later become a bottleneck as the system expands. Understanding the core hardware and software capabilities of an IoT gateway lays the foundation for secure, efficient, and scalable solutions from day one. Particularly for large-scale applications, certain features can be vital and should not be overlooked.

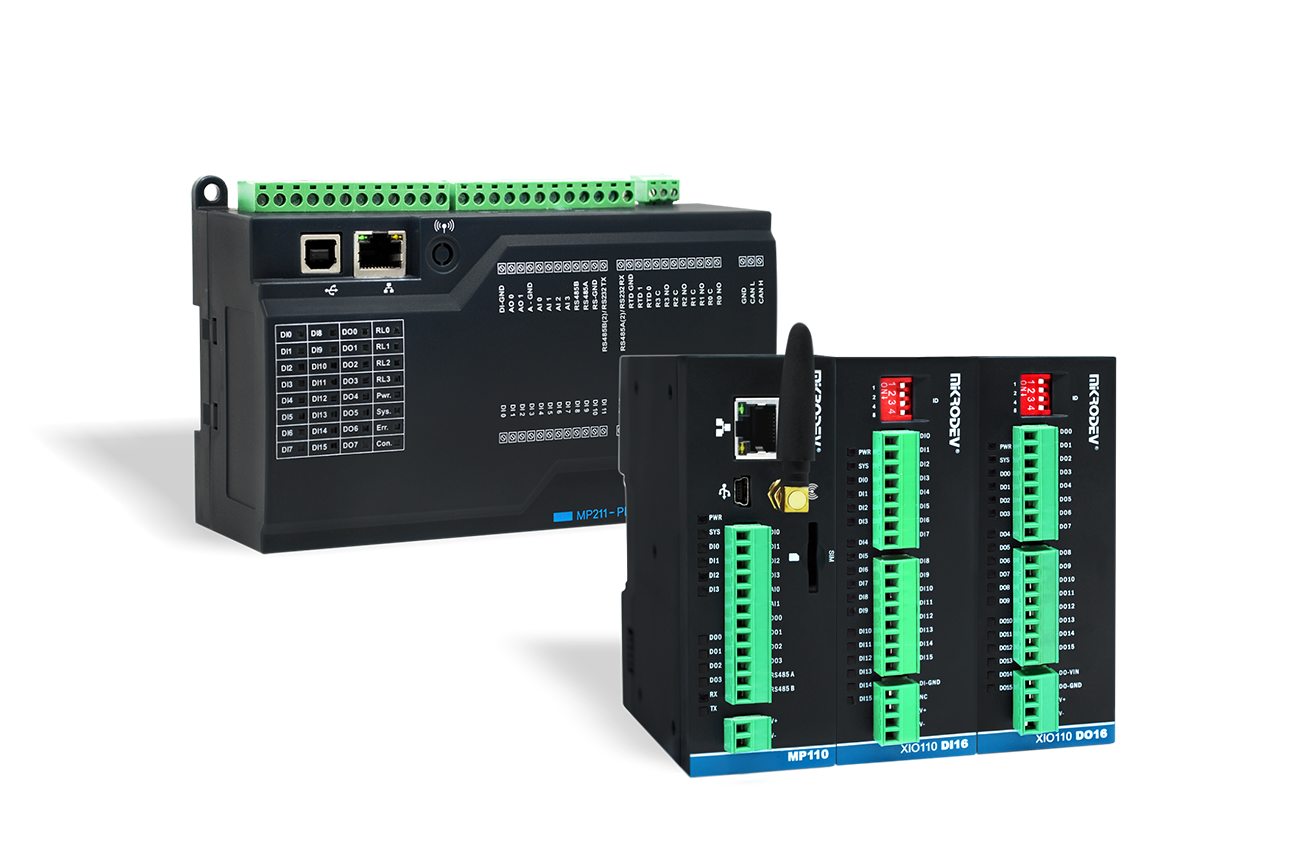

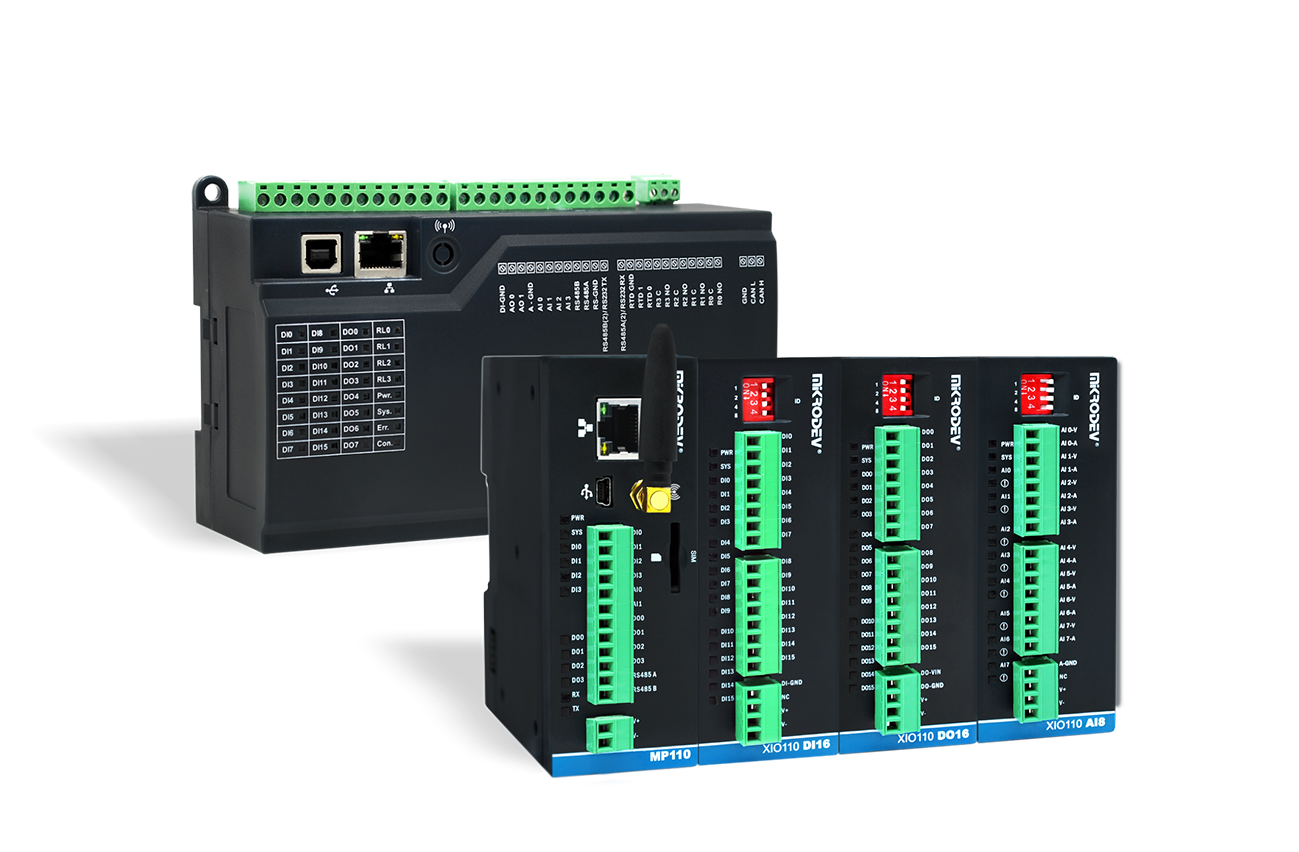

Robust Hardware Infrastructure

The processing power and memory capacity of a gateway are vital for handling data from thousands of devices without interruption. In industrial applications, high speed and stability are fundamental expectations. Adequate RAM, a powerful CPU, and advanced data-processing capabilities provide flexibility in resource management. A strong hardware base allows the gateway to:

-

Handle real-time data processing needs.

-

Manage high-volume communication traffic.

-

Minimize latency and prevent disconnections.

Multi-Protocol Compatibility and Translation Capability

In IoT systems, devices may operate with different communication protocols. Therefore, the protocol support and translation capability of an IoT gateway are crucial. Commonly supported protocols include:

-

Wireless and wired connections: Wi-Fi, Bluetooth, Zigbee, Z-Wave, Ethernet

-

Industrial communication: Modbus, MQTT, OPC UA, TCP/IP, HTTP/HTTPS

A gateway that supports multiple protocols simplifies integration and upgrades. Moreover, protocol translation capabilities ensure that devices can communicate seamlessly with each other and with the cloud. In practice, gateways with limited protocol support often create serious integration issues in medium and large-scale projects.

Edge Computing and Local Data Processing

Sending all data directly to the cloud can cause bandwidth congestion and latency issues. Therefore, an IoT gateway should support edge computing—processing data locally before transmission.

With edge analysis:

-

Real-time insights enable instant action.

-

Cloud traffic and operational costs are reduced.

-

Local automation continues even during network outages.

As IoT projects grow, edge computing capabilities become a decisive factor for success.

High-Level Security

Data security in IoT environments can never be compromised. A gateway must provide both hardware and software-level protection against cyber threats. Key features include:

-

Data encryption (in transit and at rest)

-

Secure device authentication

-

Session and access control

-

Secure remote updates (OTA)

The larger the network, the broader the attack surface—making early implementation of full security measures essential for sustainability.

Remote Management and Field Updates

Remote management is an indispensable feature of IoT projects. A gateway should be monitorable and configurable via a web or mobile panel. Additionally, firmware updates, fault detection, and device health monitoring should be performed remotely to reduce costs and simplify operations.

-

Central management interface

-

Automated update functionality

-

Error and performance reporting

Offline Operation and Backup

Continuous network availability cannot always be guaranteed. An IoT gateway must maintain core functions even when disconnected. Offline capabilities prevent data loss and ensure uninterrupted operation—crucial for industries like manufacturing, energy, and smart cities.

-

Local data storage

-

Automatic synchronization upon reconnection

-

Basic automation continuity during offline periods

Performance Criteria: Stability, Speed, and Efficiency

When selecting an IoT gateway, real-world performance is just as important as technical specifications. Acting as the central nervous system of the network, a stable, fast, and efficient gateway ensures smooth operation across all devices. Key performance metrics influence reliability, uptime, and energy efficiency—ultimately determining the project’s success.

Device Capacity and Scalability

The number of devices a gateway can support directly affects a project’s scalability and reliability. Small-scale applications may function with lower capacity, but as device counts grow, so do data and processing demands. A scalable architecture enables step-by-step expansion without redesigning the entire system.

| Application Scale | Supported Devices | Required Features |

|---|---|---|

| Small (Building Automation, Basic IoT) | 50–200 | Basic hardware, simple protocol, optional edge computing |

| Medium (Smart Grids, Campuses) | 200–1,000 | Powerful CPU, advanced edge analytics, diverse protocol support |

| Large (Factories, Smart Cities) | 1,000+ | High RAM/CPU, multi-connection support, modular design, redundancy |

Low-capacity gateways can hinder system expansion, while scalable models preserve investment value. Low latency (in milliseconds), high throughput (data processed per second), and stable performance are vital for real-time applications such as industrial automation or emergency response systems.

Protocol Support and Connectivity Options

Protocol support and connectivity variety form the backbone of IoT networks, enabling rapid integration, easy expansion, and centralized control. Thanks to multi-protocol architecture, diverse devices—from industrial machinery to smart home sensors—can coexist seamlessly within one project.

Key protocols include:

-

MQTT: Efficient low-bandwidth messaging, ideal for remote monitoring.

-

CoAP: Lightweight, suitable for battery-powered devices.

-

HTTP/HTTPS: Enables web-based and cloud integrations.

-

OPC UA: Common in industrial automation for secure machine data exchange.

-

TCP/IP, UDP: Essential for basic communication.

-

Bluetooth, ZigBee, Z-Wave: Short-range, low-power sensor networks.

-

Wi-Fi, LoRa: Wide-area, cost-effective wireless communication.

Protocol translation allows interoperability between devices using different communication standards—reducing integration time and increasing flexibility.

Security and Data Protection

Data security and privacy are non-negotiable in IoT networks. A single vulnerability in a gateway can compromise the entire system. Therefore, encryption, authentication, and secure update mechanisms are top priorities.

Key security measures:

-

End-to-end encryption (e.g., TLS 1.3)

-

Digital certificates (X.509) for device identity verification

-

Signed firmware and secure OTA updates

-

Multi-factor authentication for remote access

-

Hardware protection via TPM or PUF technology

-

Network segmentation to isolate compromised devices

A secure IoT gateway not only manages data exchange but also serves as the first line of defense against cyber threats.

Conclusion

When evaluated as a whole—features, performance criteria, protocol support, and device capacity—the right IoT gateway ensures the project’s longevity and reliability. Beyond hardware power, security and protocol flexibility must also guide the decision. Scalable capacity supports growth, while smart management and remote update capabilities reduce costs and risks.

In practice, simplicity, sustainability, and security should be prioritized over unnecessary complexity. A well-chosen IoT gateway transforms infrastructure into a resilient, efficient, and future-ready network.