OPC UA and MQTT: Definition and Fundamental Differences

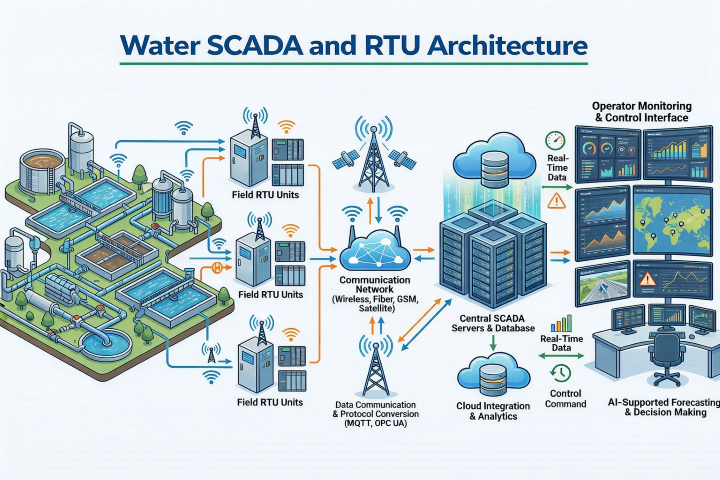

In the context of industrial communication, OPC UA (Open Platform Communications Unified Architecture) and MQTT (Message Queuing Telemetry Transport) are two frequently used but distinct data communication protocols. Both technologies have unique features regarding data sharing and processing and play important roles in Industrial IoT (IIoT) applications. However, they possess distinct differences in structure, purpose, and application areas.

What is OPC UA?

OPC UA is a standard primarily developed for use in industrial automation systems. This protocol offers a wide range of communication, from machine-level devices to cloud-based systems. OPC UA:

-

Adopts an object-oriented model. This allows data and functions to be presented within a single structure.

-

Includes internal encryption and user authentication mechanisms for security measures.

-

Provides real-time data transmission as well as historical data storage (historian), event management, and alarm systems.

OPC UA is generally preferred in situations where complex data structures need to be managed.

What is MQTT?

MQTT is a protocol designed to provide fast and lightweight communication even in low-bandwidth environments. It is specifically optimized for IoT devices. MQTT:

-

Uses the Publisher-Subscriber model. This model ensures data distribution via a message broker.

-

It is designed as a lightweight protocol to keep connection and communication overhead low.

-

It is aimed at direct message transmission, rather than being state-oriented, and is therefore generally suitable for simple data flows, such as sensor data.

Thanks to these features, MQTT is widely used in applications that require frequent data flow from remote devices.

Fundamental Differences

The differences between OPC UA and MQTT can be defined under the following headings:

| Feature | OPC UA (Open Platform Communications Unified Architecture) | MQTT (Message Queuing Telemetry Transport) |

| Application Area | Designed for complex data management in industrial automation systems. | Provides lightweight data transfer mainly between IoT devices. |

| Connection Model | Client-Server oriented. | Operates with a Publisher-Subscriber model. |

| Security Level | Incorporates more detailed security and encryption mechanisms. | Security is often provided through external methods (e.g., SSL/TLS). |

| Data Modeling | Offers extensible and object-based data modeling capability. | Simple message-based. |

These fundamental differences are determining factors in adapting both protocols to different needs. These differences must be taken into account in the integration processes within Brownfield factories.

What are Brownfield Factories and Why are they Important for IIoT?

Brownfield factories represent production sites where existing industrial facilities are located, established with various automation technologies in the past, and generally consist of heterogeneous systems. These factories can be defined as industrial environments containing older equipment and systems. The use of devices from different manufacturers, various protocols, and hardware together over time creates unique challenges in digital transformation processes.

The integration of Brownfield factories is seen as a key component in the process of adopting Industrial Internet of Things (IIoT) solutions. Since the existing infrastructures used in such facilities often consist of unstandardized protocols and legacy hardware, connecting to modern monitoring and control systems can be difficult. This indicates that Brownfield facilities have more complex system needs in terms of technological integration, unlike “Greenfield” factories, which are open to new automation investments.

The importance of IIoT for Brownfield factories stands out in the following points:

-

Cost Savings: When existing equipment cannot be completely replaced, integrating them with modern IoT solutions enables digitalization without investing in new hardware.

-

Operational Efficiency: The integration of data collection and analytics systems offers a great opportunity for the optimization of production processes.

-

Competitive Advantage: Brownfield factories catch the opportunity not to fall behind in industrial competition by making the equipment in existing facilities smarter.

-

Compatibility and Scalability: Making old systems IoT-compatible provides ease in future expansion and technology adaptation.

Despite the complex structure of Brownfield factories, communication protocols such as OPC UA and MQTT are powerful tools that enable IoT integration in such legacy facilities. These protocols provide a reliable, flexible, and standardized means of communication across heterogeneous infrastructures, allowing for comprehensive data integration.

OPC UA: Advantages and Disadvantages

OPC UA is a standard that offers flexibility, security, and interoperability in industrial automation and communication. Before deciding on its use, it is important to evaluate the advantages and disadvantages of this technology in detail.

Advantages

-

Interoperability: OPC UA enables seamless data exchange between devices from different manufacturers. Standardizing the heterogeneous structure of industrial protocols simplifies integration.

-

Platform Independence: It is designed to be compatible with various operating systems and hardware. This feature offers a suitable solution for systems across different infrastructures.

-

Security Features: OPC UA provides encryption, authentication, authorization, and data integrity mechanisms in accordance with modern security standards. It increases resilience against cyber attacks.

-

Scalability: It can be used in a wide range, from small-scale devices to large data centers. This offers the advantage of adapting to both current and future needs.

-

Rich Data Model Support: It supports a wide data model, from simple sensor data to complex process data. This facilitates the management of complex systems.

Disadvantages

-

High Implementation Costs: The implementation of an OPC UA-based system can lead to a high initial cost in terms of both software and the necessary hardware for compliance.

-

Complex Structure: The features and flexibility offered by OPC UA increase the complexity of the system. This requires technical expertise and raises the learning curve.

-

Performance Issues: Due to increased security and rich data models, performance issues may occur on low-powered devices. Additionally, delays may occur with high data volumes.

-

Compatibility with Legacy Systems: Since OPC UA is a modern standard, integration with older systems can be challenging. Adaptation to legacy devices in Brownfield factories requires additional cost and effort.

-

Difficulty in Maintenance and Support: Due to its complex structure and wide scope, maintenance and support processes can be costly and time-consuming, especially for small businesses.

OPC UA continues to be a powerful technology in industrial communication thanks to the advantages it provides. However, considering the disadvantages, the suitability of the system for the needs must be carefully analyzed.

MQTT: Advantages and Disadvantages

MQTT (Message Queuing Telemetry Transport), as a lightweight and publish-subscribe based protocol, is an attention-grabbing communication technology in the context of Industry 4.0. This protocol is specifically designed for resource-constrained devices and low-bandwidth networks. However, like any technology, MQTT has its various advantages and disadvantages.

Advantages

-

Lightweight Structure and Low Latency: MQTT offers great efficiency in low bandwidth with minimal header size. This feature makes it ideal for low-powered devices like sensors and IoT equipment.

-

Publish-Subscribe Architecture: Data exchange through a central broker allows the communication with a large number of devices to be managed simply and effectively at the same time.

-

Reliability Options: Quality of Service (QoS) levels increase the delivery reliability of messages while adapting to different scenarios. With the QoS-2 feature, a “deliver at least once” guarantee is provided.

-

Flexibility and Platform Independence: Due to MQTT’s open standard, it can be used on a wide variety of hardware and software platforms.

-

Continuity Mechanism: Data loss during connection failures is minimized with the keep-alive and Will message features.

Disadvantages

-

Broker Requirement: The need for a central broker can sometimes lead to a single point of failure. If the broker is not scaled, a bottleneck may occur under high data loads.

-

Security Limitations: There is no mechanism to guarantee security by default. Since additional protocols such as SSL/TLS are required for secure communication, complexity may increase.

-

Limited Data Structure: MQTT typically works only with plain text or raw data formats. This can complicate integration processes when working with complex data types.

-

State Ignorance: The protocol does not have the ability to monitor the state of clients, which can make tracking the overall system status difficult.

When these advantages and disadvantages are evaluated, the use of MQTT needs to be approached in balance with specific application needs and network infrastructure.

Challenges Faced in Brownfield Factories

Brownfield factories are facilities where the production infrastructure is already in place and traditional systems are generally used. Integrating industrial communication systems and implementing modernization processes can be a highly complex process in these types of factories. The challenges faced by Brownfield factories can have major impacts on both a technical and operational level.

Technical Challenges

-

Compatibility with Legacy Systems: The existing devices and control systems in Brownfield factories are often not compatible with new technologies, which complicates the integration process.

-

Protocol Diversity: Many older devices use different communication protocols. Harmonizing these systems with modern protocols like OPC UA and MQTT requires extra effort and expertise.

-

Data Security: Local network security in older systems is generally not compliant with modern standards, which can increase cyber security risks.

-

Hardware and Software Updates: Detailed planning may be required for the modernization of existing hardware and software. This increases the cost of transitioning systems to current technology.

Operational Challenges

-

Downtime Risk: Operational processes that require continuous operation of production lines may face interruptions during integration. Such interruptions can lead to serious business losses.

-

Training Requirements: Training processes must be organized for existing teams to adapt to new systems. This imposes an extra burden in terms of time and budget.

-

Investment Costs: Both the modernization and integration process require significant investment. Optimizing costs for long-term profitability can be particularly challenging.

-

Multi-Disciplinary Approach: System integration requires close cooperation between engineering, IT, and operations teams. Coordination problems between these teams can lead to project delays.

Overcoming these challenges faced in Brownfield factories is possible by implementing effective strategies and innovative solutions. Good planning of the transition process ensures that both technical and operational needs are met successfully.

Suitability of OPC UA for Brownfield Applications

OPC UA, as one of the most common communication protocols used in industrial automation systems, stands out particularly in Brownfield applications. The term Brownfield refers to existing production facilities and systems. In these types of factories, the integration of old equipment with modern technologies often poses a major challenge. However, the flexibility and scalability offered by OPC UA provide significant advantages in such integration projects.

Advantages Provided by OPC UA

OPC UA is an ideal choice for Brownfield environments because it is an object-oriented, platform-independent, and security-focused communication protocol. The following features are particularly prominent:

-

Compatibility with Legacy Systems: OPC UA offers a positive integration with various adapters and gateways developed to enable communication with existing control systems and automation equipment.

-

Data Modeling: The capacity to support complex data structures facilitates the interpretation of data produced by old machines.

-

Cross-Platform Capability: It provides seamless connectivity between different operating systems and devices, making it possible for modern and traditional systems to work in harmony.

-

Secure Communication: OPC UA includes mechanisms for encryption, authentication, and authorization for data security, enabling legacy equipment to operate securely in modern industrial networks.

Challenges for Brownfield Applications

Although OPC UA technically offers a powerful solution, the challenges encountered during implementation in Brownfield environments cannot be ignored. The following should be particularly considered:

-

Legacy Hardware: The hardware used in Brownfield facilities may need to be made compatible with OPC UA; this process may require additional adapters or software solutions.

-

Cost: Attention should be paid to the necessary investment for modernization efforts, equipment changes, and training costs.

-

System Stability: The testing and assurance process must be planned in detail to ensure that no interruption occurs during operation when using the OPC UA protocol.

OPC UA’s strong data model and wide compatibility capacity allow legacy systems to adapt to digital transformation. The protocol supports modernization in Brownfield environments while facilitating the integration process by increasing efficiency and optimizing costs.

Suitability of MQTT for Brownfield Applications

Brownfield factories often have legacy equipment, outdated protocols, and siloed data infrastructures. These environments pose challenging areas for the integration of modern industrial communication protocols. MQTT offers significant advantages in overcoming this difficulty.

Advantages of MQTT

Many of the advantages provided by MQTT are useful, especially in the transformation and modernization processes of existing systems. The suitability of this protocol in Brownfield applications is determined by the following features:

-

Lightweightness and Efficiency: MQTT can work with low bandwidth and low memory resources, thus ensuring compatibility with the features of older devices.

-

Publish-Subscribe Model: Since it does not require central communication, it simplifies integration between different devices. Data from legacy systems can be connected to modern data infrastructure with a simple structure.

-

Connection Continuity: Even if connection interruptions are common in older devices, MQTT ensures uninterrupted communication thanks to its ability to re-establish connections. This prevents downtime and stagnation in Brownfield factories.

-

Platform Independence: It offers compatibility regardless of the hardware or software platform used. This facilitates the integration of devices from multiple manufacturers.

Application Examples

Successful applications of MQTT in Brownfield factories include the modernization of sensor networks and the integration of remote monitoring systems. Older sensors can be made compatible with new systems while providing data access through MQTT. Additionally, MQTT’s security features provide an added advantage for data protection that is lacking in older systems.

MQTT’s ability to transmit data by compressing it and providing energy efficiency makes it ideal for older equipment, especially those with limited power consumption. These features create a comprehensive transformation process by adding value to the existing devices in Brownfield factories. Its offering of a dynamic match in industrial communication strengthens MQTT’s role in Brownfield scenarios.

Integration Examples with OPC UA and MQTT

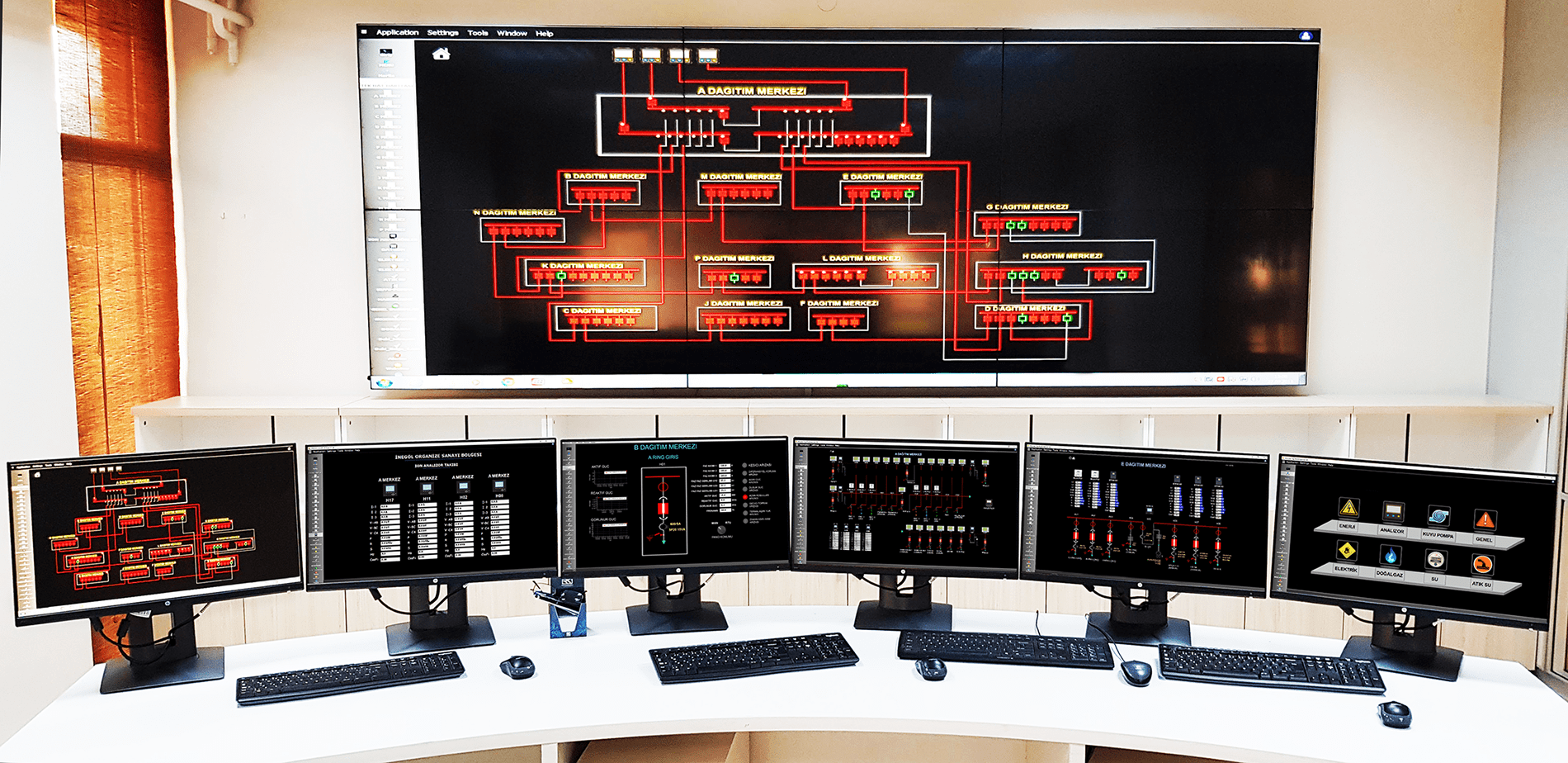

The combined use of OPC UA and MQTT in industrial communication offers a powerful solution for ensuring the seamless operation of different systems. These two standards can be successfully integrated, especially in legacy manufacturing facilities, to improve data collection, analysis, and control processes. Practical application examples of this integration are explained below.

1. Data Collection and Monitoring

OPC UA is widely used to collect precise real-time data from machine sensors and other equipment. This data is often transmitted to cloud-based platforms or a different control system via MQTT. For example:

-

Data from temperature sensors in a production facility is collected by the OPC UA server.

-

This data is then instantly transferred to an IoT platform via the MQTT protocol, where it is analyzed for energy consumption optimization.

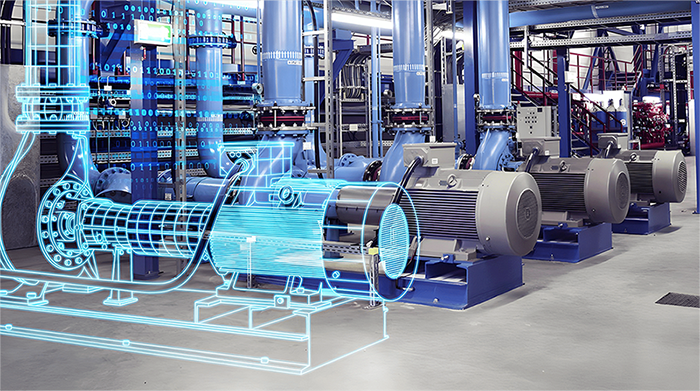

2. Legacy System Solution

The integration of old PLCs (Programmable Logic Controller) in Brownfield factories is a significant problem. OPC UA’s flexible data model can standardize the output of these PLCs. This data is then integrated with other new systems using MQTT. In such a scenario:

-

An old PLC is adapted to ensure compatibility with an OPC UA gateway.

-

Data from OPC UA is distributed to both field devices and analysis platforms with the low-bandwidth advantages of MQTT.

3. Providing High Scalability

In large production facilities, thousands of devices may need to be connected. Thanks to OPC UA’s hierarchical data structure, field-based data is collected and transferred to a central control system via MQTT. This system:

-

Easily provides instant fault notifications.

-

Elevates the data that can optimize production line performance to the operational level.

Both OPC UA’s reliable modeling capabilities and MQTT’s data transmission capacity with minimum latency effectively support the digital transformation goals of industrial processes. This integration also allows businesses to develop more sustainable solutions by maximizing the benefit from their existing investment.

A Comparison on Performance and Security Criteria

In industrial communication, protocol selection is critically important for ensuring performance and security criteria. Although OPC UA and MQTT are widely used technologies, they show significant differences in performance and security performance and design approaches, according to different architectures and usage scenarios.

Performance Criteria

In terms of performance, OPC UA stands out as a comprehensive but more complex protocol. Thanks to its inherent modeling capabilities and built-in services, it has the capacity to adapt to high data processing volumes and complex processes. However, this functional richness can increase network transmission latency and processing load. Especially when working with legacy equipment in Brownfield factories, OPC UA’s intensified resource demands can affect performance.

MQTT, as a lighter protocol, offers superior communication performance, especially in systems with limited bandwidth or low processing power. It effectively manages message traffic through the Publish/Subscribe model and provides low-latency data transmission. However, the simpler structure of MQTT messages can lead to inadequacies in the transmission of detailed data and the need to use additional software layers.

Security Criteria

One of the strongest aspects of OPC UA is its built-in security features. The protocol offers a security layer compliant with modern standards, such as data encryption, certificate-based authentication, and message integrity. These features provide a great advantage, especially in industrial environments where the protection of sensitive data is critical.

MQTT, on the other hand, comes with minimal security capabilities, as it was initially designed as an object-based communication protocol. However, security can be provided through external mechanisms like TLS/SSL. This offers flexibility but also requires special configurations and additional costs. In terms of security, the lack of a standardized security model in MQTT is a disadvantage compared to OPC UA.

Both protocols offer valuable options for different application areas and operational needs. The balance between performance and security should be determined according to the characteristics of the integrated systems and user requirements.

In Which Situation Should OPC UA be Preferred, and When Should MQTT be Preferred?

When selecting industrial communication protocols, specific application requirements and existing infrastructure must be considered. OPC UA and MQTT stand out in different usage scenarios and should be preferred in certain situations.

Situations Where OPC UA Should Be Preferred

-

Data Modeling and Semantic Richness: OPC UA offers standardized data modeling and object-oriented semantics. This feature is ideal for easy understanding and structuring of data between devices and systems in complex factories.

-

Brownfield or Complex Systems: Its ability to provide compatibility with existing systems facilitates the online integration of complex automation processes. OPC UA should be preferred, especially if the goal is to integrate older hardware with modern networks.

-

Security and Access Control: OPC UA offers built-in security mechanisms, encryption, and authentication. When data security is a priority in critical production areas, OPC UA stands out as a reliable option.

-

Real-Time Data Needs: OPC UA’s server-based structure is advantageous in situations requiring continuous and low-latency data transfer.

Situations Where MQTT Should Be Preferred

-

Low Bandwidth and Lightweight Communication: MQTT is preferred in applications that operate with low bandwidth and require high flexibility. Its use is advantageous in devices where energy efficiency is important in operation.

-

IoT and Cloud Applications: MQTT is a protocol adapted to cloud-oriented architectures. Therefore, it is used to connect IoT devices to cloud-based data analysis.

-

Simple and Fast Integration: MQTT’s minimalist structure accelerates the software and hardware integration process. Its use is suitable, especially in systems performing small and simple tasks.

-

Areas Where Network Connections are Unreliable: When working with unreliable or frequently broken network connections, preventing data repetitions and data losses is easier with MQTT’s publish/subscribe mechanism.

Important Factors in the Decision Process

The following factors should be considered when choosing between application requirements and system structure:

-

The complexity of the existing infrastructure

-

Data security demands

-

Simplification of communication process requirements

-

Suitability of the system for cloud or local operation

Selecting the right protocol ensures maximum efficiency from industrial integration.

Planning the Future in Industrial IoT Strategies

Industrial IoT (IIoT) has become one of the priority elements of digitalization strategies in many sectors. However, evaluating only the success of existing technologies is not enough in the process of planning the future; adapting to new technologies and changing market dynamics is also critically important. Businesses targeting IoT integration in Brownfield environments must have a long-term strategic vision while modernizing existing equipment and systems.

In the process of planning the future, the following key strategic steps stand out:

-

Increasing Data Collection and Analysis Capacity: The constantly increasing number of sensors and expanding data pools have brought the need for data analysis to be more comprehensive and meaningful. The flexibility offered by communication protocols such as OPC UA and MQTT contributes significantly to meeting these requirements.

-

Making Systems Compatible and Scalable: Existing machines and processes in factories need to be modernized to respond to future requirements. Especially, adding solutions like OPC UA adapters and MQTT brokers to older machines allows for the creation of a more harmonious communication infrastructure.

-

Strengthening Cyber Security and Data Privacy Measures: As digitalization increases, so do security risks. Especially as production facilities become more networked with IIoT solutions, preparing a comprehensive framework for data protection solutions becomes mandatory.

-

Determining Long-Term Technology Investments: Focusing only on current requirements can offer a short-term advantage for businesses. However, not making investments that support the growth of the IIoT infrastructure can lead to future compatibility problems and high costs. Companies’ strong collaborations with technology providers can facilitate adaptation to changing standards.

When planning these strategic steps, it should be remembered that all processes, from technological integration to operational efficiency, must support each other. Additionally, training programs for employees to adapt to digital tools should also be part of the plans.

Conclusion: OPC UA or MQTT? Making the Right Decision

Selecting the right technology in industrial communication depends on a range of factors, such as the factory’s existing infrastructure, future integration goals, and compliance with business processes. The choice between OPC UA and MQTT can be complex, especially in Brownfield factories, because existing systems must work in harmony with modern solutions. Identifying the strengths and weaknesses of both protocols is critical for making the right decision.

Strengths of OPC UA

One of the most important advantages of OPC UA is that it ensures the secure transport of industrial data. This protocol, designed with integrated security features, offers features such as data encryption, authentication, and certificate management. Additionally, thanks to its standardization, it is compatible with a wide variety of devices and is ideal for managing complex data structures. OPC UA stands out as a suitable option for meeting the needs of central control points in larger production facilities.

Strengths of MQTT

MQTT is known for offering fast data transmission and low network load. Thanks to the Publish/Subscribe architecture, it provides effective communication even in low-bandwidth networks. The simplicity of MQTT facilitates its implementation, especially in small-scale systems or IoT environments. It also offers a flexible structure in situations where multiple devices are connected simultaneously. This makes it ideal for lightweight devices, such as sensors and microcontrollers in the field.

Which Factors Influence the Choice?

Factors that influence a factory’s choice may include:

-

Existing Infrastructure: Providing easy integration with systems already present in the Brownfield environment.

-

Security Needs: The need for appropriately modeled security measures to protect critical data.

-

Data Type and Volume: The characteristics of the data to be transported and the speed requirement must be considered.

-

Cost and Resources: The implementation cost and existing human resources also determine the feasibility of the chosen protocol.

Application Scenarios and Compromise

The combined use of both protocols is also a frequently preferred method in Brownfield factories. OPC UA can be used for the secure data management of central systems, while MQTT can be ideal for the rapid collection and processing of data from field devices. Thus, a hybrid solution can be implemented for different scenarios. Combining the strengths of the protocols provides businesses with maximum flexibility and performance.