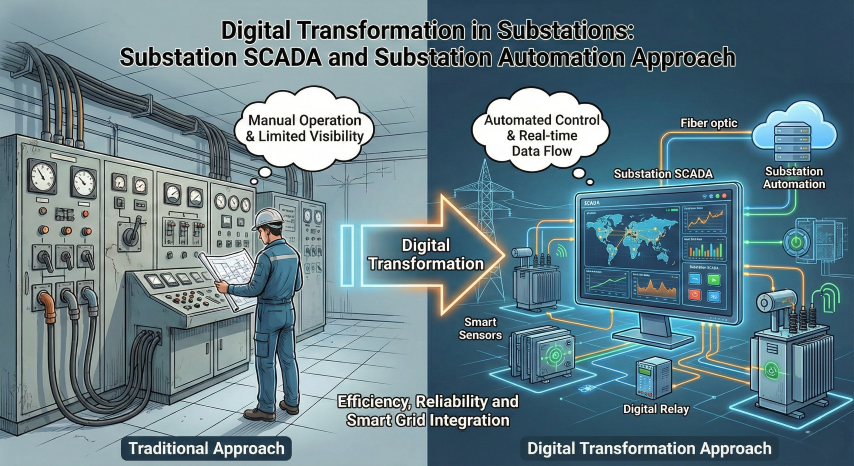

Energy is the lifeblood of modern civilization. In the process of delivering this energy from generation to the end consumer in an uninterrupted, high-quality, and secure manner, the most critical nodes are Transformer Substations. Facilities that were once managed through manual operations and analog panels are now being replaced by fully digitalized, self-deciding, and remotely managed Substation Automation systems.

In this article, we will examine in depth the anatomy of modern substation automation, Substation SCADA architecture, the role of field-end units such as RTUs, and the universal languages spoken by these systems: the IEC 61850 and IEC 60870 protocols.

What Is Substation Automation?

Substation automation is the management of protection, control, monitoring, and measurement functions in a transformer substation through an integrated system. These systems are designed to minimize human error, reduce fault response times, and increase grid reliability (by improving SAIDI/SAIFI indices).

In traditional systems, an operator had to be physically present on site to see the status of a circuit breaker or measure the oil temperature of a transformer. With automation, this data is digitized at millisecond-level resolution.

A modern automation system consists of three main layers:

Station Level: SCADA and HMI screens where operators monitor the system.

Bay Level: The layer containing protection relays and control devices.

Process Level: The physical layer where current/voltage transformers, circuit breakers, and disconnectors are located.

Mikrodev aims to eliminate blind spots in the field through its Energy Automation Solutions that ensure seamless data flow between these layers.

The Backbone of the System: Substation SCADA

Substation SCADA is the software platform that enables monitoring of a transformer substation from a local or remote control center (NCC – Network Control Center). Unlike water SCADA systems, energy SCADA solutions require much faster response times and millisecond-level time-stamped data recording known as “Sequence of Events.”

During a fault (for example, a short circuit), the time between a protection relay issuing a trip command and the alarm appearing on the SCADA screen is critical. At this point, advanced SCADA software such as ViewPLUS provides operators with the following capabilities:

Single Line Diagram Visualization: Dynamic monitoring of power flow, busbar statuses, and switching elements.

Trend Analysis: Historical analysis of power, current, voltage, and frequency values.

Alarm Management: Prioritized alarms that enable operators to focus on critical faults.

The Field Controller: RTU (Remote Terminal Unit)

Undoubtedly, the most critical hardware component of substation automation is the RTU (Remote Terminal Unit). Although PLCs are widely used in industrial automation, RTUs are preferred in the harsh electromagnetic environment of substations and for wide-area communication requirements.

An RTU collects data from field relays, analyzers, and sensors, processes it, and transmits it to the control center. What distinguishes a substation RTU from an ordinary controller is the following:

Time Synchronization: Ability to time-stamp events with 1 ms accuracy using GPS or NTP.

Protocol Conversion (Gateway Capability): Enables legacy field devices (e.g., Modbus) to be converted to modern protocols.

Harsh Environment Resistance: Resistant to strong magnetic fields created by high voltage and extreme temperatures.

Modular RTU Stations developed by Mikrodev are designed specifically for these requirements of the energy sector. They collect data directly from the field via I/O cards and communicate with intelligent electronic devices (IEDs) through communication ports.

The Language of Energy: Communication Protocols

The key to success in substation automation is ensuring that devices communicate with each other and with the control center in the “correct language.” Two major standards stand out in the energy sector: IEC 60870 and IEC 61850.

A. IEC 60870-5-101/104: Long-Distance Communication

This protocol family was developed for telecontrol (remote supervision).

IEC 60870-5-101: Operates over serial communication (RS232/485). Commonly found in legacy systems.

IEC 60870-5-104: TCP/IP (Ethernet) based. It is the most widely used protocol today.

Mikrodev devices include the IEC60870 protocol stack as a built-in feature. This allows an RTU in a transformer substation to securely transmit data via fiber optic or 4G/LTE to a Load Dispatch Center located kilometers away. Even if data packets are lost, the protocol ensures data integrity, and missing data is later completed through backfilling.

B. IEC 61850: The Future of Substations

IEC 61850 is not just a protocol but a global standard for substation automation. It enables the replacement of traditional copper cabling with fiber optic networks.

MMS (Manufacturing Message Specification): Provides communication between SCADA systems and IEDs (Intelligent Electronic Devices).

GOOSE (Generic Object Oriented Substation Event): Horizontal communication between devices. For example, when a protection relay detects a fault, it can issue a “trip” command directly to another relay via a GOOSE message over the network within milliseconds, without passing through SCADA.

Mikrodev RTU and Gateway solutions act as a bridge by acquiring data from field relays in compliance with IEC61850 standards and transmitting it to upper-level systems (such as TEİAŞ or EDAŞ control centers).

The Importance of Gateway and Protocol Conversion

Many transformer substations in Türkiye and worldwide have a “hybrid” structure, where 20-year-old legacy relays operate alongside modern digital analyzers. This creates the need for Protocol Converters.

Mikrodev devices function as powerful gateways and can perform the following conversions:

-

Modbus RTU/TCP devices → IEC 60870-5-104 control centers

-

IEC 60870-5-103 (legacy protection relay protocol) → IEC 61850 systems

-

DNP3 devices → SCADA systems

This flexibility allows facilities to be integrated into modern SCADA systems without requiring complete replacement (retrofit projects).

Cybersecurity and Modern Threats

Transformer substations are critical infrastructures and primary targets for cyberattacks (e.g., Stuxnet, BlackEnergy). Therefore, cybersecurity is not optional but mandatory in Substation Automation systems.

RTU and SCADA systems used must support:

-

VPN (Virtual Private Network)

-

Encrypted data transmission (SSL/TLS)

-

User authorization and logging

-

Firewall capabilities

Mikrodev’s DCS and RTU product family is designed with industrial cybersecurity standards in mind, enabling communication through secure tunnels that are closed to the outside world but accessible to authorized users.

The Path to Smart Grids

In an era where energy demand is increasing and renewable energy sources (solar and wind) are being integrated into the grid, Substation Automation is no longer a luxury but a necessity. A properly designed Substation SCADA and RTU architecture not only enables remote monitoring but also provides predictive maintenance, reduces outage durations, and lowers operational costs.

With IEC-compliant hardware and software developed through domestic engineering capabilities, Mikrodev positions itself as a reliable partner for the energy sector in this digital transformation journey.

In Summary: Why This Technology?

| Feature | Traditional Method | Modern Automation (Mikrodev & IEC61850/60870) |

|---|---|---|

| Monitoring | Manual, on-site observation | 24/7 Remote, Real-Time |

| Fault Detection | Based on notification | Automatic Alarm and SMS/Email |

| Data Logging | Paper-based logs | Digital Database, Trend Analysis |

| Communication | Bundles of copper cables | Fiber Optic & Ethernet Network |

| Intervention | Dispatching field teams | Remote Control (Open/Close) |

Selecting the right protocols and using flexible hardware to future-proof your energy infrastructure will accelerate the return on your investment.