SCADA systems, being used for remote monitoring and control of data elements in automation processes, play a crucial role in various sectors such as energy, petrochemicals, natural gas, food industry, manufacturing, transportation, and even in automation systems for drinking water and wastewater management. As mentioned in the previous article “What is SCADA?” agricultural irrigation systems, both in urban and rural areas, are another important application area where SCADA systems are extensively utilized. These systems are employed to monitor and control factors such as water levels in the soil, weather conditions and the needs of living organisms.

It is a fact that farm irrigation systems play a crucial role in ensuring efficient water management and optimal crop growth. With the advancement of technology, automated irrigation systems have gained popularity among farmers. These systems, equipped with irrigation controllers, provide precise control over water distribution, resulting in improved water efficiency and reduced water waste. The integration of automated watering systems into farm irrigation practices allows farmers to automate the irrigation process, saving time and effort while ensuring consistent water supply to crops. By implementing an automated irrigation system, farmers can optimize water usage, minimize water-related expenses, and enhance overall farm irrigation efficiency.

Therefore, the use of SCADA systems in agricultural irrigation processes enables automatic control of water flow, regulation of water quantity and pressure, monitoring of water resources, and even conducting soil and plant analyses in some cases. The benefits of employing SCADA systems in drinking water supply, wastewater management and agricultural irrigation applications can be summarized as follows:

- Reduced operating costs

- Increased operational efficiency

- Facilitated detection and correction of production process errors

- Enhanced production efficiency

- More efficient utilization of water resources.

Mikrodev’s Specific SCADA Solutions for Agricultural Irrigation Applications

As it is underlined above the implementation of irrigation automation and control systems has significantly transformed irrigation farming practices. By utilizing an irrigation system controller, farmers can precisely manage and control the irrigation process, ensuring optimal water distribution and minimizing wastage. These systems enable farmers to automate the farm watering system, allowing for consistent and efficient watering of crops. With irrigation automation, the entire crop irrigation system can be monitored and adjusted remotely, providing convenience and flexibility to farmers. This level of control and automation enhances the overall productivity and effectiveness of crop irrigation systems, resulting in improved crop yields and resource efficiency.

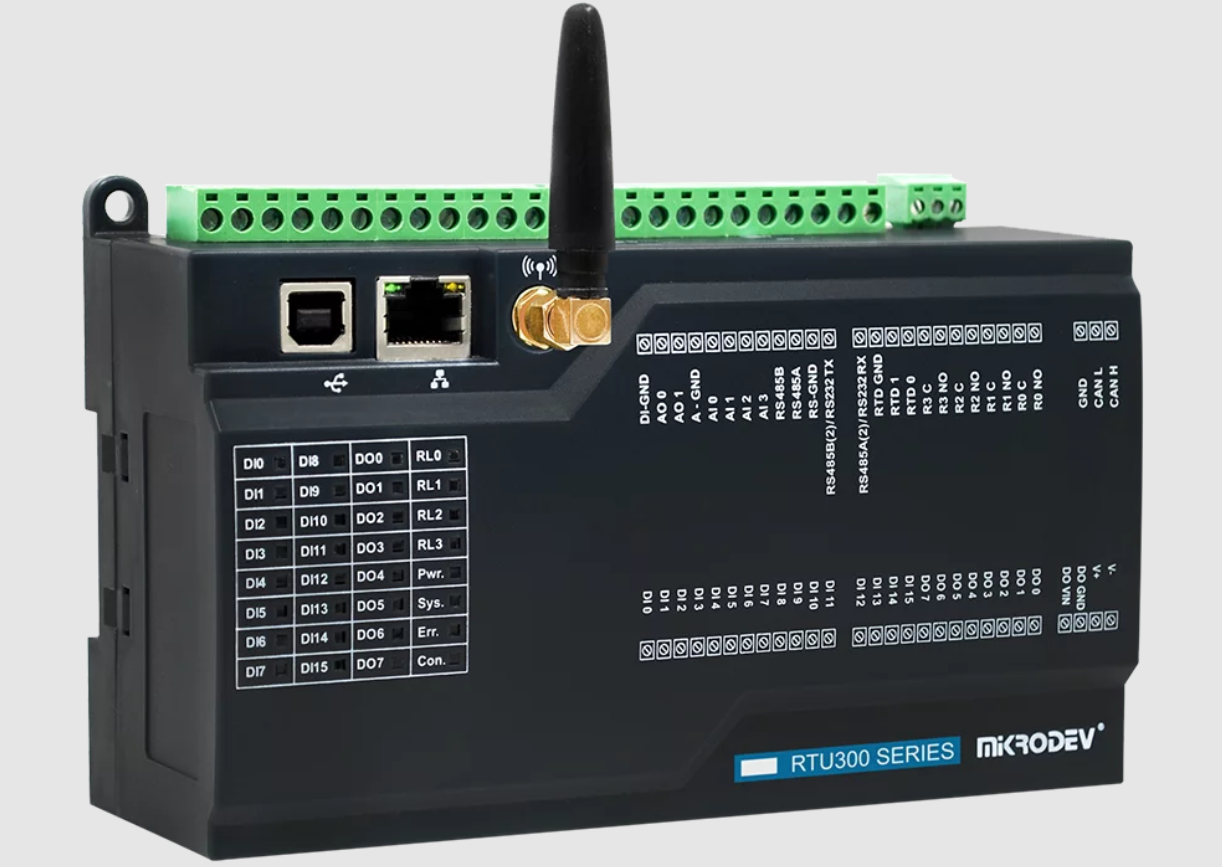

Mikrodev, a leading provider of SCADA systems, confidently offers its products for such various projects including automatic irrigation systems, pivot irrigation systems, and greenhouse automation. The control of agricultural irrigation systems can be performed either automatically or manually. In pivot irrigation applications, each irrigation arm can be managed using Mikrodev’s PLC or RTU products by adjusting the timing. The system allows individual configuration of each irrigation area for analysis purposes.

Furthermore, ambient temperature and humidity values can be monitored based on data obtained from sensors. The control and monitoring of motors, pumps, and valves involved in agricultural irrigation can also be carried out through SCADA systems using Mikrodev products. Additionally, potential fault data is monitored through remote systems, data can be recorded using the remotely managed system, and historical data can be analyzed through comprehensive reporting. The automation of agricultural irrigation systems significantly enhances the productivity and efficiency of agricultural production while promoting the sustainable use of limited water resources both locally and globally through technological advancements.

Water resource management has been a critical issue globally, including in Turkey. Proper and efficient utilization of water resources is vital, and it directly relates to the principle of “water management” in today’s world. Many regions in Turkey have a dry climate, and the available water resources for agricultural purposes are limited accordingly. Additionally, factors such as environmental pollution, unregulated industrial activities, and unplanned and excessive farming continuously contribute to the deterioration of water quality in the country. To ensure fair and efficient water resource management, effective strategies need to be implemented, and organizations should leverage modern technologies such as automation systems to maximize their benefits.

In this context, the utilization of automation applications supported by Mikrodev’s SCADA systems for agricultural irrigation, water treatment, and flood prevention enables more efficient water resource management for the future. Mikrodev’s SCADA software ensure reliable operation in areas such as energy, resource optimization, and remote access, contributing to Turkey’s progress in automation through domestically developed SCADA systems. By utilizing Mikrodev’s SCADA solutions, technological independence is also strengthened at the local level. Visit the solutions page to explore Mikrodev SCADA products applied in water & wastewater systems, wastewater treatment automation, and agricultural irrigation, and enhance the efficiency of your business by leveraging Mikrodev’s capabilities.

For instance, you can review the TIGEM Pivot Arm Irrigation, Fertilizing & Seed Dressing SCADA System project to gain insights into the application of Mikrodev SCADA systems in agricultural irrigation. Feel free to contact Mikrodev teams to learn more about similar-scale applications and how they can benefit your specific requirements.