Success in the field of automation begins with choosing the right control system. RTU (Remote Terminal Unit) and PLC (Programmable Logic Controller) are two fundamental devices used to safely manage critical operations in many industries. While both lie at the heart of automation, they carry significant differences in terms of function and application. The RTU vs. PLC comparison serves as a guide for those wanting to understand which device is more advantageous in which usage areas and control systems.

While RTUs are generally preferred for data collection and transmission in remote locations, PLCs are powerful in complex process control. Choosing the right tool in industrial automation increases the efficiency and reliability of the system. In this article, you will find a detailed guide regarding RTU vs. PLC differences, usage areas, and control systems.

What are RTU and PLC? Basic Concepts

Understanding the foundations of control systems and industrial automation opens the door to making informed choices about RTU vs. PLC, differences, usage areas, and control systems. RTU and PLC are two main devices that frame automation, each with different environments and job descriptions. In this section, you can focus on the basic functions of both systems and for what purpose they are used in practice.

Definition and Working Principle of RTU

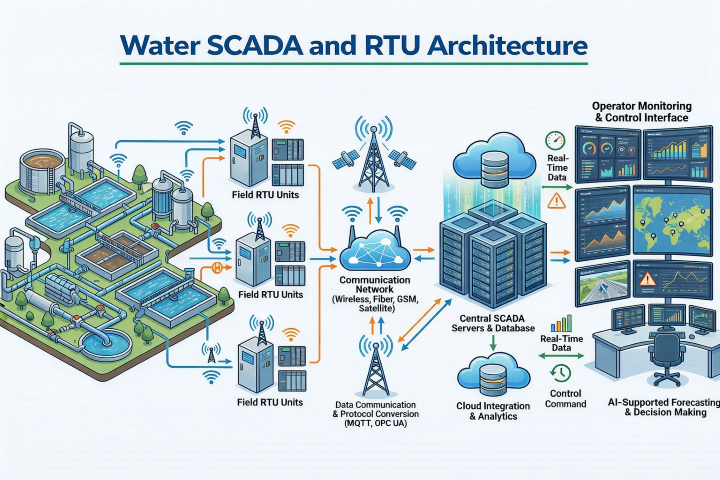

RTU is known as Remote Terminal Unit and is generally used in facilities located far from the central control center. Its main purpose is to collect data from sensors or devices at remote points and transmit it securely to a central system. Energy grids, water treatment plants, and oil and gas fields are the main examples where RTUs stand out.

The role of an RTU in the system is as follows:

-

It collects analog or digital data received from sensors and measuring devices in the field.

-

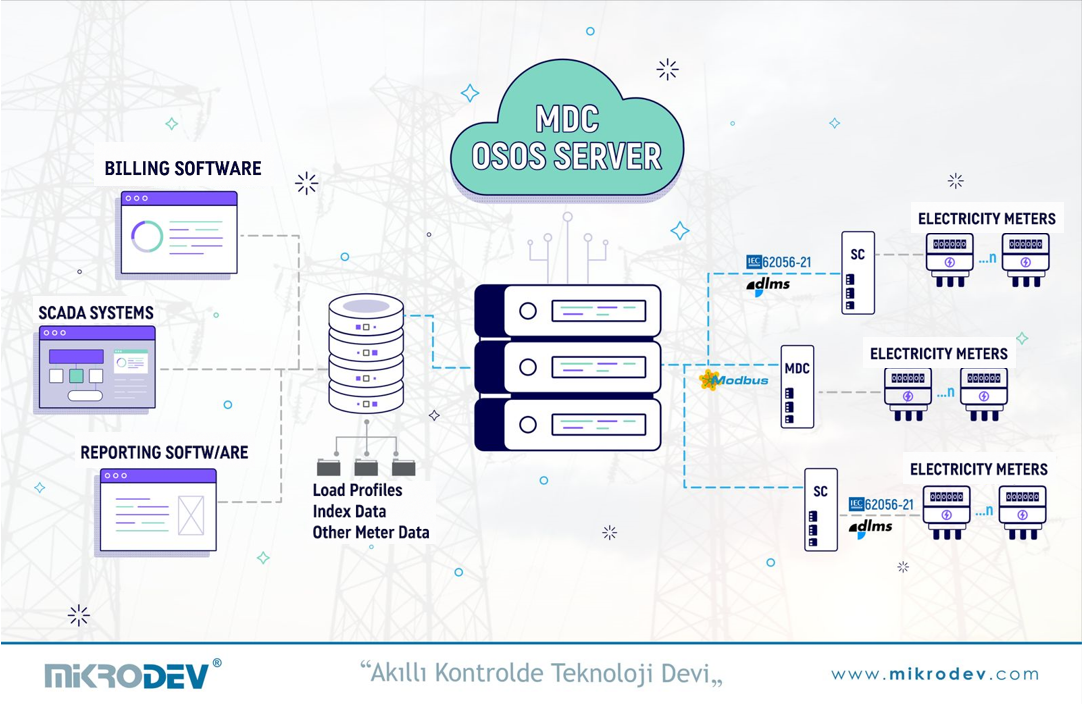

It transmits the collected data to the central SCADA or control center at specific intervals.

-

It decodes commands coming from the central system and applies them to the remote device.

-

It performs critical functions such as monitoring power lines, controlling water levels, or detecting electrical faults.

This structure ensures secure and stable data transmission in infrastructure projects. RTUs are generally manufactured to be durable enough to operate uninterrupted for a long time in harsh, hard-to-reach environments. Thanks to communication protocols (such as DNP3, MODBUS, IEC standards), they integrate seamlessly with different systems and can take responsibility in wide networks. The RTU stands out with its reliability; it is resistant to sudden weather conditions, humidity, and dust.

Definition and Working Principle of PLC

PLC, or Programmable Logic Controller, is seen as the brain of modern industrial automation. We encounter PLCs especially in production lines in factories, robotic systems, and wherever machine automation exists. The fundamental feature of the PLC is to analyze information coming from numerous inputs and outputs in real-time and produce outputs with the correct logic.

You can summarize the place of PLC in automation as follows:

-

It manages the operation of machines requiring fast and precise control.

-

Thanks to its programmable structure, changes can easily be made in business processes.

-

Complex process flows are developed via languages like Ladder Logic.

-

PLCs are indispensable in systems such as conveyor belts, automatic packaging machines, and quality control stations.

-

It safely performs tasks like robot movement, temperature and pressure control, or automatic data collection during production.

A PLC system processes data coming from the field instantaneously, makes decisions according to the control program loaded by the operator, and ultimately controls output elements such as actuators. Its fast response and modular structure make it easy to adapt to sudden changes. Flexibility and high processing capacity are among the most sought-after features in factory automation.

Summary:

While RTU is built on data collection, monitoring, and remote communication; PLC is used to make fast decisions and manage machines on-site in a precise manner. When looked at from the perspective of RTU vs. PLC, differences, usage areas, and control systems, the areas where each system is strong are easily distinguished. This distinction plays a strategic role in the success of industrial automation.

Technical Differences Between RTU and PLC

When it comes to RTU vs. PLC, differences, usage areas, and control systems, distinctions in technical specifications are critical for the right choice. The hardware structure, software approach, ease of programming, and communication protocols of these two automation elements determine the preferred solution in dozens of different industries. Below, you can find in detail why RTU and PLC differ from a technical perspective.

Hardware Differences

First of all, the physical designs and component sets of RTU and PLC are configured according to different needs. RTU is produced to be resistant to harsher environmental conditions, mostly in accordance with field conditions. Especially for RTUs that have to work without failure in cabinets in remote regions or open areas, there is special protection against dust, humidity, and heat.

Technical differences standing out on the hardware side are:

-

Analog Input/Output (I/O) support: RTU devices generally have a higher number of analog I/Os. They are ideal for collecting continuously variable data such as water levels, voltage, and temperature.

-

Digital Input/Output speed: PLCs are known for wide digital I/O ports and high processing speeds for fast communication with local machines.

-

Data processing and storage: RTUs possess powerful memories and data logging capabilities for continuous data collection and communication with central systems.

-

Mounting and space usage: Thanks to their modular structures, PLCs provide easy integration with different equipment in factory automation. RTUs are generally mounted in field panels as a single unit.

The table below summarizes the basic hardware differences between RTU and PLC:

| Feature | RTU | PLC |

| Durability | Suitable for harsh environments | Focused on use in enclosed facilities |

| Analog I/O | Higher number and variety | Limited or requires additional modules |

| Digital I/O | Sufficient but not fast | High speed, multi-port |

| Data Storage | Advanced (long-term logging) | Generally low capacity |

| Layout | Single piece, field type | Modular, rack-mounted |

Software and Ease of Programming

When RTU vs. PLC, differences, usage areas, and control systems come to the agenda, software and programming also play a major role. RTU devices mostly have configuration-focused and ready-made software templates. Users generally complete the field installation in a short time by determining the basic parameters on the device.

On the PLC side, processes operate over programmable logic. This is advantageous for flexible and customizable processes. For example, the movements and processes of complex machines or robotic systems can be coded step by step with Ladder Logic.

We can list the software differences as follows:

Programming in RTU:

-

Fast setup with drag-and-drop interfaces and predefined functions.

-

Configuration possibility without needing complex coding knowledge.

-

Network connection and data collection stand out more.

Programming in PLC:

-

Possibility of detailed programming with languages such as Function Block Diagram (FBD) and Structured Text (ST), primarily Ladder Logic.

-

High flexibility in machine controls, rapid reconfiguration.

-

Strong software infrastructure for real-time decision-making and local automation.

Communication Protocols

In industrial automation systems, communication between devices is important for secure and fast data transfer. The communication protocols supported by RTU and PLC diverge at this point.

Prominent protocols in RTU:

-

DNP3, MODBUS, IEC 60870/101/104: With these protocols, RTUs can send data to and receive commands from SCADA systems over wide geographical areas.

-

Provides secure, long-distance communication with a remote device or central system.

-

Generally used with low bandwidth and security measures.

Prominent protocols in PLC:

-

Profibus, EtherNet/IP, Modbus TCP: Provides high-speed, point-to-point, or over-the-network local communication.

-

Suitable for real-time data flow with in-factory machine integration, smart sensors, and actuators.

-

Less latency and higher connection speed.

Input and Output Features

Another technical distinction in the comparison of RTU vs. PLC, differences, usage areas, and control systems is based on input and output (I/O) features:

I/O Features in RTU:

-

Support for a large number of analog inputs provides an advantage for collecting different data types from field sensors.

-

Digital outputs control field devices at a basic level but do not require high speed.

-

Focused on alarms, status tracking, and measurement.

I/O Features in PLC:

-

Allows for very fast signal processing and machine control thanks to digital I/Os.

-

Analog I/O support is usually increased via modules.

-

Has the capability to manage a large number of inputs and outputs simultaneously in complex automation steps.

In terms of RTU and PLC, both the system’s connection with the environment and the type of devices it controls bring these differences to the fore. For example, while an RTU is more suitable for a sensor network measuring water levels, a PLC is more correct for a packaging machine automation.

Usage Areas: Where are RTU and PLC Preferred?

Under the heading of RTU vs. PLC, differences, usage areas, and control systems, the prominent preference areas of both technologies are clear. RTUs and PLCs are preferred according to their tasks and the needs of the environment they are in. Application and sector examples concretely show which system stands out under which conditions.

Areas Where RTU is Preferred

RTUs are used in wide and challenging geographical regions, especially in points that are difficult to access, requiring long-term and reliable data collection and remote control. RTU’s unique advantages allow it to stand out in many sectors.

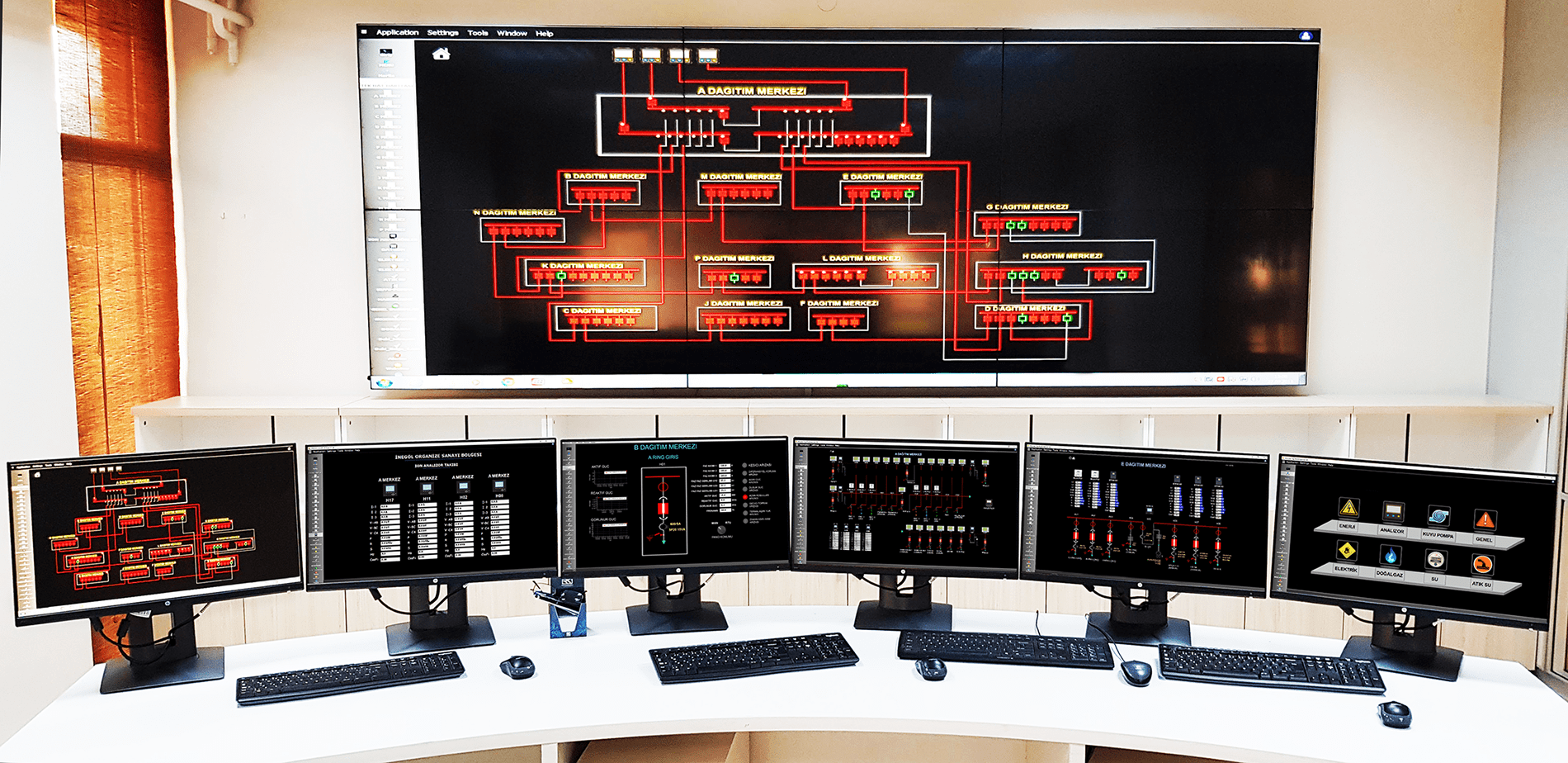

- Electric Grids:In examples such as intercity electricity transmission or substation management, the infrastructure usually spreads over hundreds of kilometers. Each transmission point must be monitored on-site, and faults must be detected quickly. RTU makes every point of the grid remotely controllable via wireless networks or GSM/M2M communication.

-

Short case example: An energy distribution company ensured the uninterrupted operation of the grid by transmitting instantaneous voltage and current data to the central SCADA using RTUs in all substations on the intercity transmission line.

-

- Water Management and Wastewater Facilities:RTUs used in water treatment plants, dams, or water distribution systems deliver level, flow, or pressure measurements at remote points to operators at the center. In this way, operators can safely perform operations such as pump control even from thousands of kilometers away.

-

Short case example: A metropolitan municipality established an efficient water management system by tracking level and quality measurements with RTUs in water tanks and wells at different points of the city.

-

- Oil and Natural Gas Fields:In risky and dispersed fields like the energy sector, RTU use is practically essential. RTU devices collect critical information such as pressure and temperature monitoring in pipelines, wellheads, or pump stations, and valve status at the center, offering intervention opportunities when necessary.

-

Short case example: A natural gas firm increased system safety and took quick action in faults by installing dozens of RTUs along the pipeline route.

-

Areas Where PLC is Preferred

PLCs stand out in production facilities where multi-step and complex control operations requiring fast response exist. They offer flexibility with their programmable structures and are used safely in process control.

- Production Lines and Automation Facilities:From automotive to food production, it offers speed and accuracy together in many different sectors. It processes signals coming from sensors in belt systems in real-time and ensures the precise management of robot arms.

-

Short case example: In an automotive factory, the flow of all welding robots in body assembly is synchronized with PLC; thus, quality standards are maintained, and production speed increases.

-

- Machine and Process Automation:In conveyors, packaging machines, or filling systems, PLCs process a large number of input-output signals within seconds. Operators can easily change the program and adapt to different products or tasks.

-

Short case example: In a bottling facility, adjustable filling processes for bottles of different weights were managed with PLC, thus enabling product changeovers without stopping the line.

-

- Quality Control and Monitoring:PLCs work seamlessly in image processing, quality control, or measurement stations requiring advanced algorithms.

-

Short case example: An industrial software firm instantly detected defective products and separated them from the line with camera systems connected to PLC at the exit of the production line.

-

Comparative Table: RTU and PLC Usage Areas

The table below summarizes the main application areas where RTUs and PLCs are predominantly preferred:

| Application | Suitable for RTU | Suitable for PLC |

| Electric Grid | ✔ Substation, transmission line control | ✘ |

| Water Management | ✔ Distribution, treatment, dam monitoring | ✘ |

| Oil/Gas Field | ✔ Pipeline, well, station control | ✘ |

| Production Line | ✘ | ✔ Automation, robot management |

| Packaging/Machinery | ✘ | ✔ Conveyor, filling, quality control |

| Wastewater Facility | ✔ Field data collection, remote monitoring | ✘ |

Conclusion: Right System, Right Application

When RTU vs. PLC, differences, usage areas, and control systems are considered, what is critical is obtaining maximum efficiency in the appropriate area with the appropriate technology. RTUs provide data collection and remote monitoring in scattered and challenging geographies; PLCs create a difference with rapid decision-making and high control capacity in production and automation processes. Both systems play a key role in the safe and sustainable operation of modern industry according to need.

Advantages and Disadvantages: Comparing RTU and PLC

To make the right choice under the heading of RTU vs. PLC, differences, usage areas, and control systems, it is important to know the prominent advantages and potential disadvantages of both systems. Field needs, budget constraints, technical expectations, and the application environment are decisive on the decisions to be taken. In this section, you can find the pros and cons that decision-makers will face in practice in a clear, simple, and comparative manner.

Advantages and Disadvantages of RTU

RTUs generally stand out in environments requiring continuous monitoring in wide areas under harsh conditions. However, it is useful to consider some limitations.

Advantages:

-

Durability and Reliability: Withstands harsh outdoor conditions, temperature, and humidity changes at a high level.

-

Remote Monitoring and Control: Offers communication opportunities over long distances in remote and decentralized field applications.

-

Low Power Consumption: Can operate for a long time in regions with weak energy infrastructure.

-

Easy Integration: Integration into SCADA and central control systems with common protocols (DNP3, IEC, etc.) is comfortable.

-

Ease of Installation and Maintenance: Installs quickly as a field panel. Maintenance is generally possible via remote software updates.

Disadvantages:

-

Limited Programming Ability: Flexibility is low in comprehensive or complex control operations.

-

Slow Response Time: Not suitable for automation tasks requiring real-time rapid response.

-

High Initial Cost: Especially custom productions for harsh field conditions can be more expensive.

-

Limitation of Hardware Modularity: Adding extra I/O or functions is more difficult compared to PLCs.

Short Note: When purchasing an RTU, criteria such as communication capability, resistance to the environment, and maintenance requirements need to be evaluated. Especially in energy, water, and infrastructure management, low operating costs provide long-term investment.

Advantages and Disadvantages of PLC

PLC systems are the first choice of businesses seeking dynamic and customizable control in factory and process automation. Nevertheless, they harbor some disadvantages within themselves.

Advantages:

-

Fast and Flexible Control: Complex processes are managed instantly with a real-time, high-speed processor.

-

Advanced Programming Options: Detailed automation and control are easily provided with languages like Ladder Logic, FBD.

-

Modular Structure: Can be expanded according to capacity needs by adding I/O modules.

-

Ease of Maintenance and Spare Parts: Service times are short with standard hardware and software.

-

Low-Scale Investments: Offers cost-effective solutions in small and medium-scale automation needs.

Disadvantages:

-

Sensitivity to Environmental Conditions: Requires special protection in excessively dusty, humid, or hot environments.

-

Short Distance Communication Limitation: Extra communication hardware and infrastructure may be required for long distances.

-

Energy Dependence: Generally requires a fixed energy source; the system may go offline during outages.

-

Limited Direct Compliance with SCADA: In some models, extra software may be required for switching to external protocols.

Short Note: When planning a PLC; existing facility infrastructure, rapid response requirements, expansion needs, and ease of maintenance operations should be evaluated. In industrial automation and process control, ease of maintenance and low initial investment are decisive for most businesses.

Comparative Advantage-Disadvantage Table

The table below is prepared for decision-makers who want to quickly compare the advantages and disadvantages of RTU and PLC systems:

| Criteria | RTU Advantage | RTU Disadvantage | PLC Advantage | PLC Disadvantage |

| Durability | High | – | Medium | Low |

| Programming | Easy configuration | Limited flexibility | Flexible and detailed | More complex |

| Communication | Long-distance communication | Slow data transfer | Fast, local | Short-distance |

| Expandability | Low | Hardware constraints | Easy modular | – |

| Cost | Low operating, high initial investment | – | Low initial investment | High maintenance |

| Energy | Low consumption | Capacity limited | Standard/dependent | Sensitive to power outage |

When making an investment decision regarding RTU vs. PLC, differences, usage areas, and control systems; priority should be given to the geographical conditions of the application area, the control speed required by the equipment, sustainable maintenance, and network integration. Both systems can provide complete and strong infrastructures in their own fields, but both current and future needs must be considered when making a choice.

Which is More Suitable for Which Control System? Selection Criteria

In the context of RTU vs. PLC, differences, usage areas, and control systems, choosing the device suitable for the actual need accelerates the return on investment and offers maximum efficiency and safety in the field. Making a correct decision at this point requires not only looking at the technical specifications of the devices but also considering elements such as the scale of the project, ease of maintenance, and remote monitoring requirements. Below, the main criteria the reader needs to ask themselves when choosing a device and the conditions where each system stands out are explained in detail.

Key Question: What Will Be Controlled and Where?

One must start with the most basic question: What is the process the system will control, and where does this process take place?

-

Is it a site in a wide and scattered area requiring remote monitoring and low energy?

-

Or is it an enclosed production line requiring precise, fast, and complex automation?

These questions reveal the initial distinction clearly. While RTU offers advantages in remote monitoring and harsh environmental conditions, PLC stands out in factory automation with its speed and flexibility.

Basic Selection Criteria

The following topics offer the most useful roadmap when choosing a device:

-

Application Area and Physical Conditions:

-

RTU: Systems working in a scattered manner outdoors in a wide geography such as electric grids, water distribution, natural gas lines, and infrastructure projects.

-

PLC: Enclosed facilities, production lines, factory environments, and machine-focused automation projects.

-

-

Communication and Remote Management:

-

RTU: More suitable for sending data to and receiving commands from central systems like SCADA over long distances. Supports different protocols.

-

PLC: Provides fast data exchange with local machines and sensors, but is limited in wide-area communication.

-

-

Scalability (Expandability):

-

RTU: Optimized for fixed and specific functions, the need to add a large number of I/Os is rare.

-

PLC: Can be easily expanded by adding new modules thanks to its modular structure; the system grows as needs change.

-

-

Ease of Maintenance and Service:

-

RTU: Low maintenance need even in harsh field conditions, advantage of remote monitoring and software update.

-

PLC: Rapid hardware replacement with standard modules, widespread service, and spare part access.

-

Questions You Need to Ask for Practical Selection

When the reader needs to choose which device, answering these questions clearly will find the right path:

-

Is the area to be controlled physically scattered and remote?

-

Is continuous remote monitoring and data transmission a priority?

-

Are external factors like temperature, humidity, and dust dominant in the environment?

-

Will the system frequently require expansion and adding new functions?

-

Does the automation process require very fast and precise decisions?

-

Must your existing infrastructure work together with upper-level systems like SCADA, ERP?

-

Are ease of installation and maintenance, and total cost of ownership important to you?

These questions not only serve as a starting point for system administrators but also prepare the ground for planning their investments safely.

Conditions Where Each Device Shines

Below you can clearly see in which type of scenarios RTU and PLC stand out.

Situations to Prefer RTU:

-

Very remote, challenging, and energy-limited field applications

-

Need for uninterrupted data collection and long-term recording requirements

-

Central monitoring and command over the network

-

Critical infrastructure projects not requiring frequent access

Situations to Prefer PLC:

-

High-speed process control and real-time connection between machines

-

Automation in constantly changing production or expandable lines

-

Processes requiring local decisions and having no tolerance for short latency

-

Need for flexible programming and rapid commissioning

Comparison of Integration, Scalability, and Maintenance

In the table, devices can be quickly evaluated in terms of scalability, ease of integration, and maintenance:

| Criteria | RTU | PLC |

| Scalability | Fixed, few additional modules | Modular, easy to grow |

| Remote Monitoring | Strong, seamless over long distances | Limited, factory-internal focused |

| Integration | Advanced compliance with SCADA systems | Compatible with local network and standard protocols |

| Maintenance | Remote software update, low service frequency | Spare part access is fast, easy intervention |

Both device types are successful in their own fields; however, making a choice according to the expectations and environment of the project always ensures the highest performance.

Selection Summary: Which System to Choose?

The quick table below serves as a guide for decision-making:

| Scenario/Function | RTU Suitable | PLC Suitable |

| Remote and widespread field application | ✔ | |

| Fast process and production line | ✔ | |

| SCADA integration need | ✔ | |

| Easy expansion and update | ✔ | |

| Challenging environmental conditions | ✔ | |

| Low energy requirement | ✔ | |

| Complex control and programming | ✔ |

Managing the selection process systematically in terms of RTU vs. PLC, differences, usage areas, and control systems is directly related to long-term success. To fully benefit from the advantage offered by each device, field requirements and growth plans must definitely be taken into consideration.

Every detail standing out under the heading of RTU vs. PLC, differences, usage areas, and control systems offers a strong roadmap for businesses when making decisions. RTU stands out in infrastructure projects by providing reliable data collection and monitoring in wide and challenging fields. PLC, on the other hand, offers an effective solution in complex automation processes in enclosed facilities with its fast and flexible control structure.

Both systems take on critical roles in industrial automation with their own strengths; the right project and choice suitable for the need determine the efficiency and sustainability of businesses. Readers can develop the most suitable solution by considering their needs in the field and long-term expectations.

It is important to follow sectoral resources for in-depth comparisons with up-to-date information on the subject. Readers sharing their experiences or questions can create a more effective information network in this field. Everyone empowered with knowledge on RTU vs. PLC, differences, usage areas, and control systems achieves more effective results in automation projects.