Industrial automation is the cornerstone of process control in modern manufacturing facilities. PLC (Programmable Logic Controller) systems are used to manage automation control, which is the foundation of industrial automation. In PLC programming, the use of calendar and timing functions is highly significant because effective time management affects various factors such as production efficiency, error prevention, energy conservation, and workforce optimization.

Calendar and Timing Functions: Two Key Elements

Calendar functions are programming functions that work with date and time information and trigger specific operations based on this data. In industrial automation applications, calendar functions play a critical role in managing time, synchronizing processes, and organizing workflows effectively. Timing functions, on the other hand, control specific time periods or events in PLC programs. These functions ensure that certain events occur within specific time intervals, organize process sequences, and support error prevention.

1. Timing of Production Processes:

Efficient timing is crucial for the smooth operation of industrial production processes. Initiating work orders, maintenance tasks, or product changes at the right time enhances production efficiency. Calendar functions assist in accurately scheduling such events, while timing functions control specific time intervals or events.

2. Energy Conservation:

Reducing energy costs is a top priority for many industrial facilities. Automatically shutting down processes at specific times or activating devices that enhance energy efficiency contributes to energy savings. Both calendar and timing functions facilitate energy management.

3. Maintenance Management:

Machine maintenance needs to occur at regular intervals. Calendar functions ensure that maintenance tasks are performed on time. For example, maintenance for a machine can be automatically scheduled when the usage time or product count reaches a certain level. Timing functions can also help monitor maintenance periods.

4. Data Logging and Reporting:

Calendar and timing functions are essential for data logging and reporting. Automatically recording and reporting events or production data that occur over a specific period makes it easier to monitor and improve business processes.

5. Workforce Management:

Managing worker working hours or shifts is crucial for enhancing workforce productivity. Calendar functions can be used to automatically schedule shift changes, holidays, or break times. Timing functions assist in organizing worker shifts.

6. Error Prevention:

Calendar and timing functions can be utilized to protect automation systems from faulty conditions. For instance, they can generate alerts or safely halt the automation process if a specific device doesn’t operate for a certain duration.

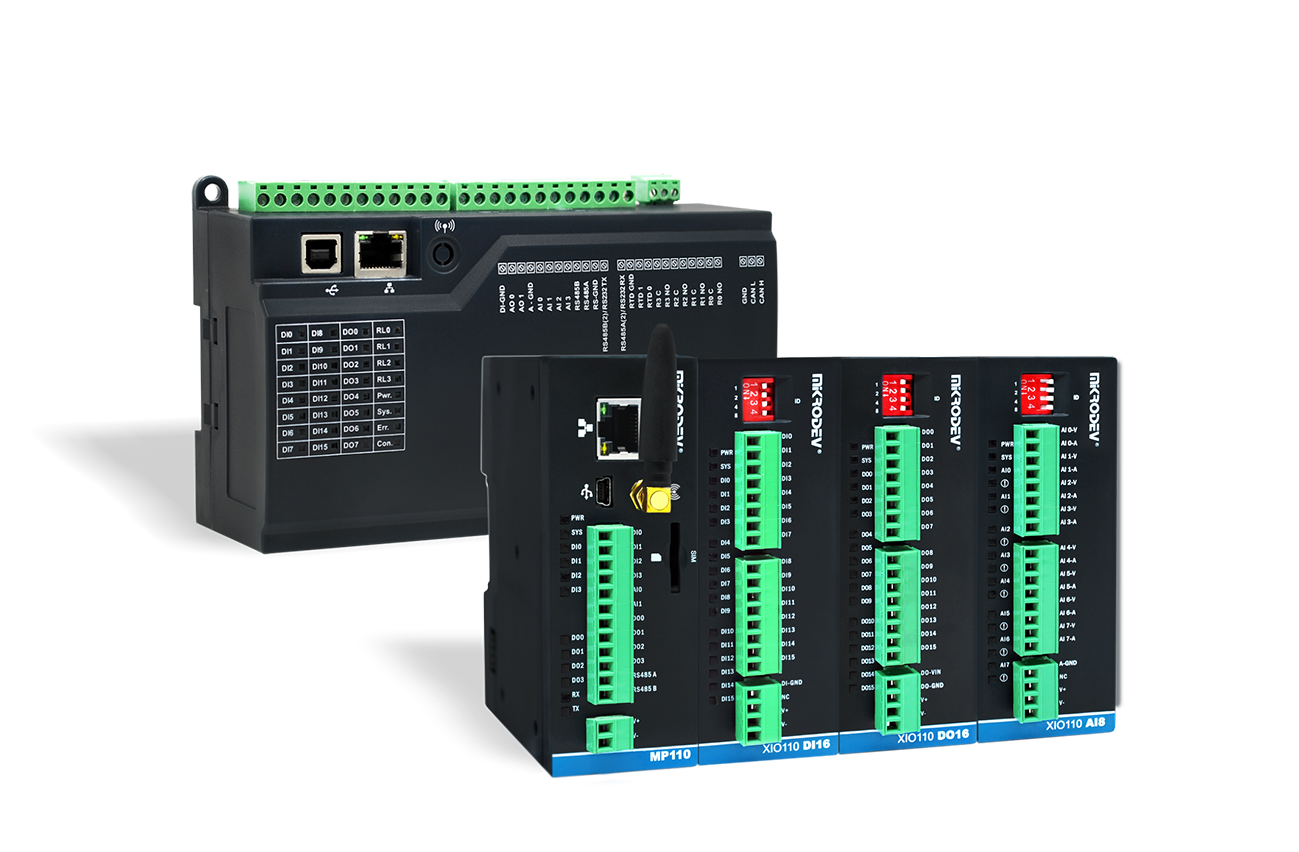

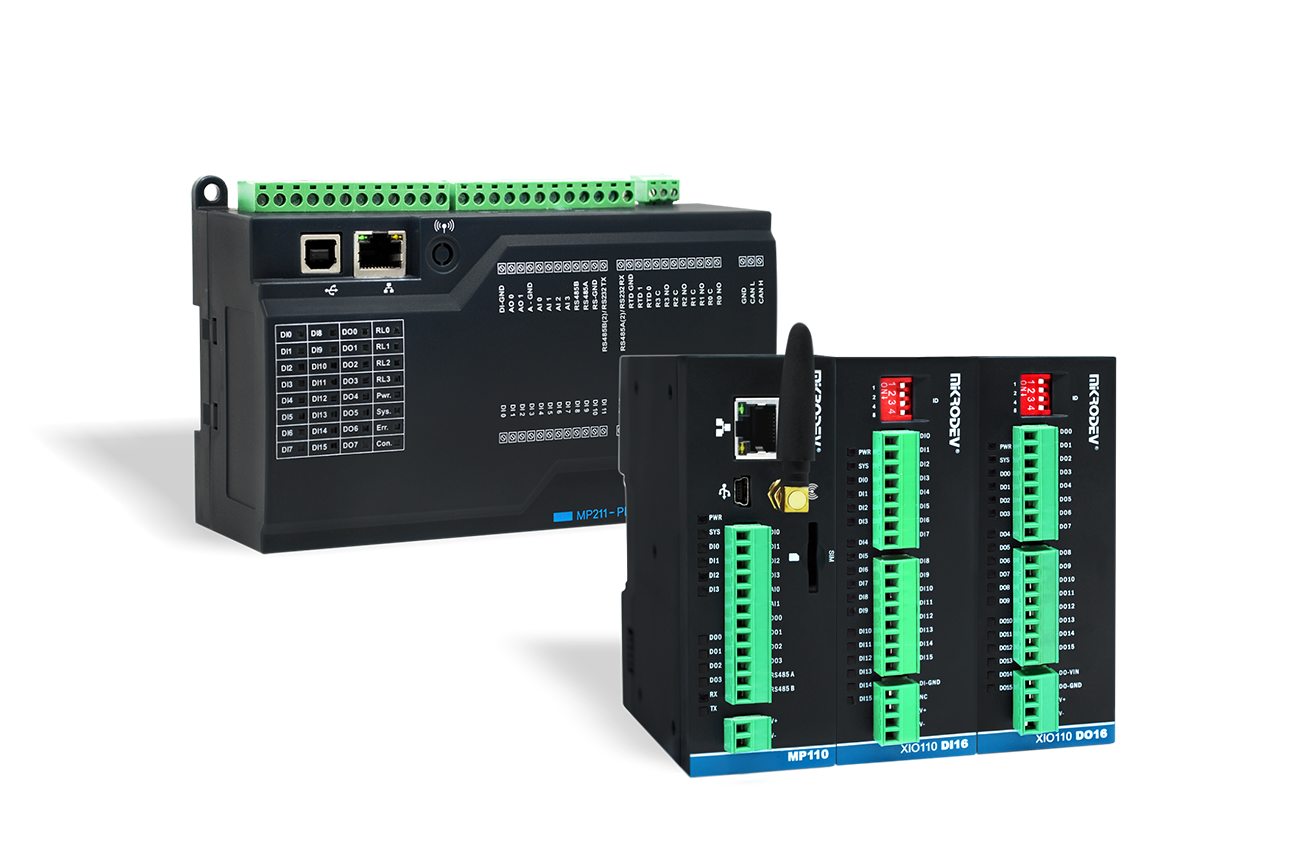

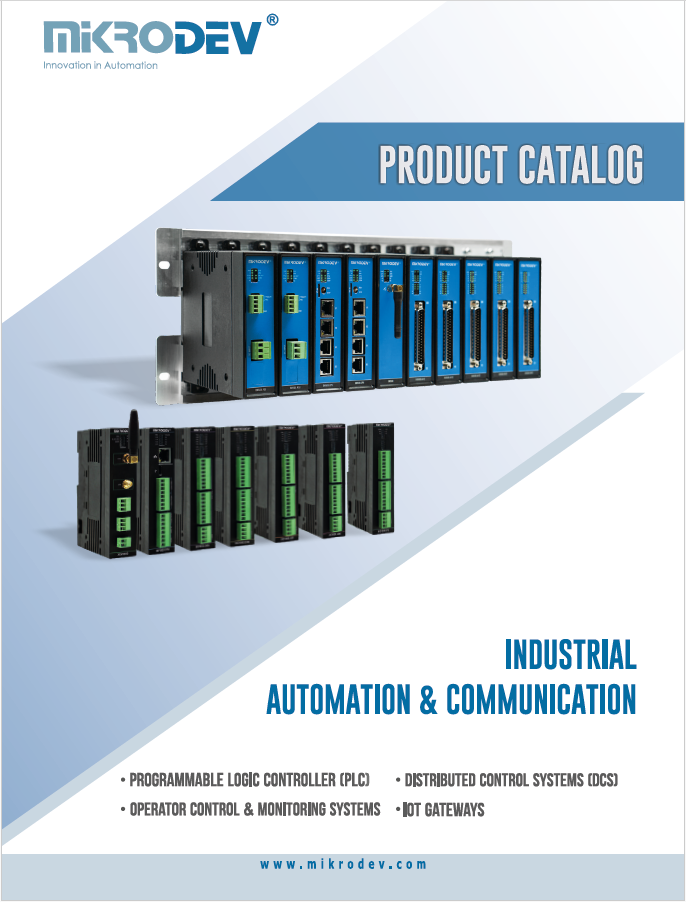

Mikrodev PLC programming interface provides 7 different timing functions and 14 different calendar functions. This wide range of functions enables effective time management, ensuring that business processes run more efficiently and reliably. Properly planned calendar and timing functions can lead to cost savings, worker satisfaction, production quality, energy conservation, and various other advantages. Therefore, engineers designing and programming industrial automation systems should prioritize the effective use of these functions. With technological advancements, the critical role these functions play in the success of industrial automation is bound to increase further.

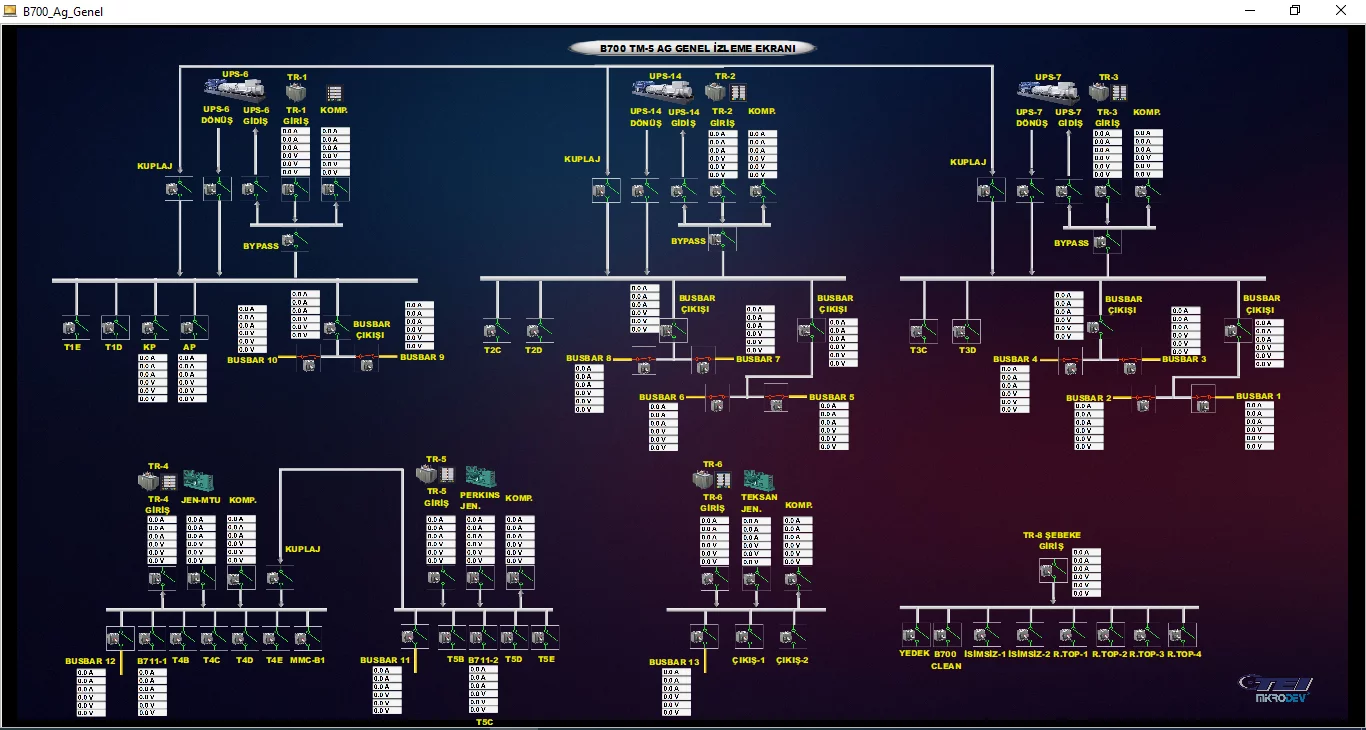

To summarize, PLC programming is at the heart of industrial automation systems and plays a major role in automation technologies today. In particular, advanced PLC automation systems, such as Mikrodev PLC, are widely used in industrial automation solutions. These systems provide advanced functionality, reliability and flexibility for a variety of industrial automation applications. For example, PLC software programs often provide communication between programmable logic controllers and electrical, energy automation, SCADA systems and other automation solutions. This makes it possible to manage industrial processes more efficiently, accurately and reliably. Domestically produced PLC solutions, such as Mikrodev PLC programming, continue to be an important player in industrial automation applications; because Mikrodev’s domestically produced PLC solutions solidify its position in the sector with its unique software and hardware support. In addition, developments in PLC programming and application areas increase the efficiency of industrial automation and enable better control of processes.