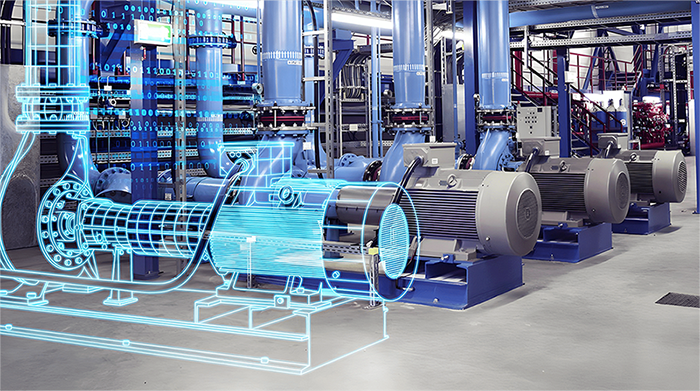

High pressure, aging infrastructure, invisible leaks, and rising energy costs are the silent enemies of water and wastewater networks. The solution is clear: measure, manage, reduce. In 2025, the combination of water SCADA, pressure management, DMA, leak detection, pump control, telemetry, and RTU integration is the most reliable way to achieve this goal at a reasonable cost. An RTU (Remote Terminal Unit) is a smart field unit that collects data from sensors in the field, securely transmits this data to the center, and performs local control when necessary. The expected result is simple: fewer bursts, less water loss, lower energy consumption, and faster intervention.

Reducing Water Loss with Pressure Management: How RTU and Water SCADA Work Together?

Pressure directly affects leakage flow rate. Let’s think simply: reducing pressure by 10% in most networks reduces the leakage flow rate by approximately 10% to 20%. The RTU reads pressure (bar), flow (m³/s), and level (m) sensors, sends them to the center via telemetry, and the water SCADA manages the setpoint based on this data. Pressure Reducing Valve (PRV), valve, and pump commands are given remotely and automatically. With real-time monitoring, alarm thresholds, and event logging, the operator responds instantly to changes in the field.

The risk is different on the wastewater side. Level increases, backflow, and flooding stand out more than pressure surges. The RTU monitors level and flow at the pumping station, runs the pumps in a safe sequence, and discharges the water before a flood. This holistic architecture works with the trio of water SCADA, telemetry, and RTU.

Real-Time Pressure and Flow Tracking with Field Sensors and Telemetry

Pressure sensors, magnetic flow meters, and level sensors are the three most common.

-

The RTU collects this data within seconds or minutes and sends it via cellular networks (4G, NB-IoT) or RF.

-

Practical suggestion: 1-minute sampling, 15-minute reporting.

-

In case of packet loss, the RTU writes to the buffer memory and retransmits.

-

Encrypted connection and authentication are necessary for telemetry security.

RTU hardware is fundamental to reliable operation in the field. For hardware features, you can look at the RTU300 Series Remote Terminal Unit link.

Pressure Reducing Valve Control: Adaptive Setpoint and Night Mode

PRVs reduce leakage flow by lowering the pressure when demand drops. Two setpoints, such as 5.0 bar during the day and 3.8 bar at night, provide quick gains. In the case of optional, demand-based control logic, the RTU automatically adjusts the setpoint by looking at flow and minimum pressure measurements. The RTU operates safely with local PID even if the central connection is lost. Soft opening and closing are configured against the risk of overpressure and pressure surges.

Alarm and Event Management: Burst, Pressure Surge, Low Level

If an instantaneous pressure drop and simultaneous flow increase are observed, a potential burst alarm is triggered. Threshold-based and rate-of-change-based rules are used together. Escalation logic on the water SCADA, with SMS and email notifications, transforms event logs into work orders for the maintenance team. Dynamic thresholds based on DMA are recommended to reduce false positives.

Level and Backflow Monitoring for Wastewater

Critical parameters in wastewater are level and flow. The RTU monitors the level sensor at the pumping station and issues pump start and stop commands. In the event of a rapidly rising level due to rain, alarm and bypass gate control are activated to prevent backflow and flooding. Odor control equipment and ventilation fans are also monitored and reported.

For a general framework on SCADA architecture and water applications, the What is a SCADA System content is a useful starting point.

Step-by-Step Leak Detection with DMA: Collect Data, Analyze, Repair

DMA (District Metered Area) is the division of the network into small, isolated metering zones. The goal is to find where the leaks come from faster. With RTU and water SCADA, inlet and outlet flows are monitored, and the differences become visible. The leakage signal is extracted with night minimum flow, continuous flow traces, and anomaly analysis. Then field confirmation is done, and verification is performed with valve closure tests and acoustic listening if necessary.

DMA Design and Meter Placement: Inflow-Outflow Balance

DMA boundaries are established with closable valves and inlet meters. At least one inlet, and preferably a meter on every outlet line, should be included. Bypass lines are included in the meter to prevent leaks from being hidden. Meter accuracy directly affects leak estimation, so a calibration plan is necessary. Map data and a simple hydraulic model bring clarity to the design.

Night Minimum Flow Analysis: Catch Leaks Early

The inlet flow is monitored between 02:00 and 04:00, when consumption is at its lowest. The difference between the expected base consumption and the measured value is the leakage signal. Moving average and median filters are applied to the RTU data to reduce noise. Seasonal and weekday vs. weekend differences are evaluated separately. If there is a persistent increase, the team is directed to the field.

RTU, Water SCADA, and AI-Powered Anomaly Detection

Pressure-flow-time data from the RTU is normalized in the water SCADA. Equipment maintenance and planned work periods are marked so that false alarms are not generated. Simple machine learning methods, such as seasonal ARIMA or isolation forest approaches, can flag sudden deviations. Keeping the model explainable strengthens decision support for field teams. Data ownership and privacy are protected, and access is logged.

Field Confirmation, Repair Plan, and KPI Tracking

Steps in the field must be clear: valve closure, pressure tests, acoustic listening. Repair priority is determined by the amount of water loss, customer impact, and excavation cost.

The following KPIs make progress visible in the field:

| KPI | Goal |

| Non-Revenue Water | Monthly decrease with a percentage target |

| Number of Faults | Reduction based on area and type |

| Average Intervention Time | Time elapsed from incident to repair |

| Leak Repair Time | Time between detection and closure |

The right RTU selection is critically important in water and wastewater projects. For an overview of the product range, the basic RTU concepts in the DM100 Series RTU Products article can be reviewed.

Pump Control and Energy Efficiency: Smart Station Management

Energy expenditure is high in pumping stations. RTU and water SCADA play a central role in pump control. Keeping the pressure constant with Variable Frequency Drives (VFDs) significantly reduces energy consumption. Equipment life is extended with starting sequence, equal aging, maintenance counters, and vibration-temperature monitoring. Level-based control and flood prevention scenarios in wastewater pumping stations support continuous operation in the field.

Pressure Stabilization and Savings with Variable Frequency Drives

Simple physics: if speed decreases, flow and pressure decrease, and energy decreases approximately cubically. The RTU adjusts the VFD setpoint with pressure feedback. Lower pressure at night, controlled increase during peak demand, keeps the system stable. Anti-surge and soft-start extend pipe life and reduce the risk of failure.

Starting Sequence, Equal Aging, and Maintenance Alerts

Equal aging is performed by cyclically changing the pump A-B-C sequence. Maintenance alerts are generated from data such as operating hours, number of start-stops, and temperature. The RTU can switch to local fault mode and activate backup pumps. Extending component life is a saving as important as energy.

Flood and Cavitation Protection Based on Reservoir and Pumping Level

A minimum level lock is essential to protect pumps when the reservoir is at a low level. In the event of high level and heavy rain, the bypass or second line opening scenario is activated to prevent flooding. The risk of cavitation is monitored with suction line pressure and vibration data, providing early warning.

Remote Command and Safe Shutdown Scenarios

Commands from SCADA are processed with safe interlock in the RTU. If communication is interrupted, the safe state is applied, and the last valid setpoint, local timed program, and soft stop are activated. Role-based access and dual confirmation are used to prevent unauthorized commands.

RTU Selection, Installation, and Security: Field Resilience, Central Trust

The right RTU is resilient to real field conditions and communicates with the right protocols. The number of inputs/outputs, power supply options, battery backup, IP protection class, and temperature range are basic parameters. Communication is planned according to the field with 4G, NB-IoT, LoRaWAN, or Ethernet options. On the protocols side, standards such as Modbus, MQTT, and DNP3 facilitate water SCADA compatibility. Panel layout, grounding, lightning protection, and cable shielding determine reliability. In cybersecurity, encryption, VPN, strong passwords, role-based authorization, and regular patching are essential.

For a detailed product family example, the Industrial RTU Device RTU300 and DM100 Series RTU (Remote Terminal Unit) for different protocol options can be examined.

Hardware Requirements: I/O, Power, and Protection

-

Analog I/O: 4-20 mA pressure, level inputs.

-

Digital I/O: Pulse output meters, dry contact alarms.

-

Power Supply: 12 or 24 VDC, solar panel option.

-

Backup: Internal battery for 8-12 hours.

-

Protection: IP65 and above, wide temperature range, strong EMC.

Communication and Protocols: The Right Choice for the Field

4G if coverage is available, NB-IoT in deep indoor areas, LoRaWAN in rural areas.

If Ethernet is available, the wired connection is stable and low-latency.

Protocol selection: Modbus RTU/TCP for simple field devices, MQTT for cloud and IoT, DNP3 for event timestamp and security.

TLS and certificate management are essential for a secure connection.

Cybersecurity: Encryption, VPN, Authorization, and Monitoring

Change default passwords, enable multi-factor access, leave only necessary ports open. Use VPN tunnel, TLS 1.2, and current cipher suites. Separate user roles, log every action performed. Regularly update SCADA and RTU software, and run the patch schedule. Periodically test the backup and disaster recovery plan.

ROI and Roadmap: Measure, Correct, Scale in 90 Days

The simple return on investment approach aggregates three main fronts: reduced water loss, energy savings, and reduced fault costs.

Recommended 90-day plan:

-

Selection of a pilot DMA

-

RTU and sensor installation

-

Threshold and alarm setting

-

Night minimum flow analysis

-

First repairs and reporting

If success metrics are met in 6-12 months, scaling and standardization are planned for the entire network.

Field examples and application notes on the subject are consistent with municipal publications and operator experience.

Those interested in architectural selection and the software side can find a comprehensive summary on the Industrial SCADA Solutions page.

Conclusion

This approach means less leakage, more balanced pressure, lower energy consumption, and faster intervention. In 2025, the trio of RTU, telemetry, and water SCADA offers a reliable framework for water and wastewater networks. Immediate two-step suggestion: a) Establish a pilot DMA and measure night flow, b) Try adaptive setpoints on the most critical PRVs. Start the roadmap today, and see results tomorrow. The keywords are naturally repeated in the flow: pressure management, DMA, leak detection, pump control, telemetry, RTU, water SCADA.