RTU stands for “Remote Terminal Unit” in English. Used in industrial automation systems, RTU is a type of hardware component used to increase the functionality of a device. These modules are used to extend the existing features of a device; for instance, a computer’s expansion modules can increase the computer’s memory capacity or add more ports.

Frequently used in industrial automation and remote monitoring systems, RTUs play an essential role in many industries. In this article, we will briefly explain what remote terminal units are, how they work, and the RTU units and devices offered by Mikrodev.

What is RTU?

In the remote terminal unit definition, RTU stands for “Remote Terminal Unit,” RTU units perform data collection, control, and monitoring functions in industrial automation systems.

How do Remote Terminal Units work, and what is their working principle?

RTUs or remote terminal units collect data from field devices, process it, and transmit it to the control center, allowing operators to monitor and control it in real-time. Remote units communicate with field-level devices, process this data, and transfer it to the primary control system to help make decisions.

Remote terminals used to perform data acquisition and control functions in industrial automation systems collect data from sensors and share this data with a central control system. By means of that, industrial automation systems can be managed more effectively.

What is an RTU Board?

An RTU board refers to a control panel where RTU devices are mounted or deployed. These boards collect and transmit data from the points where field devices are connected.

RTU panels, where remote terminal units are mounted, are generally used to control devices used in industrial automation systems.

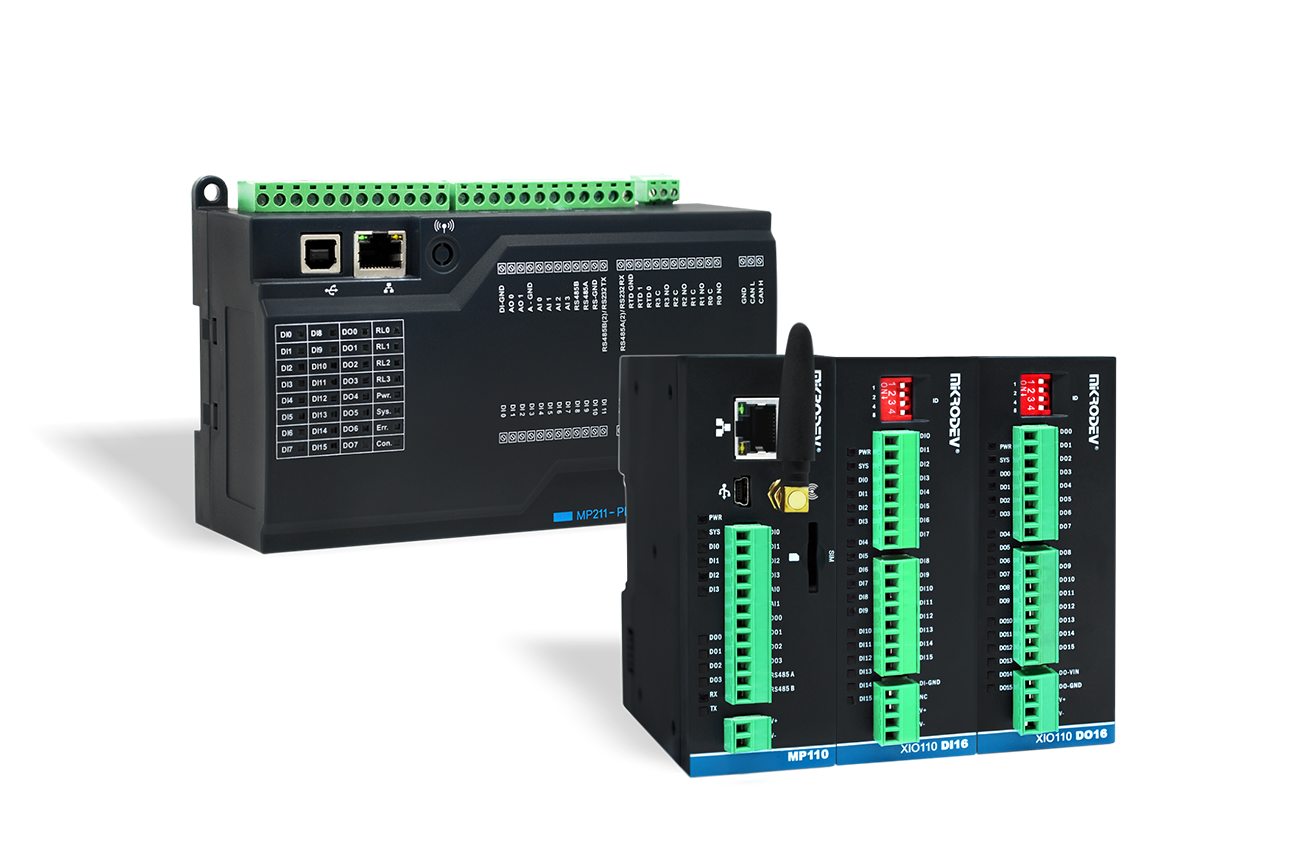

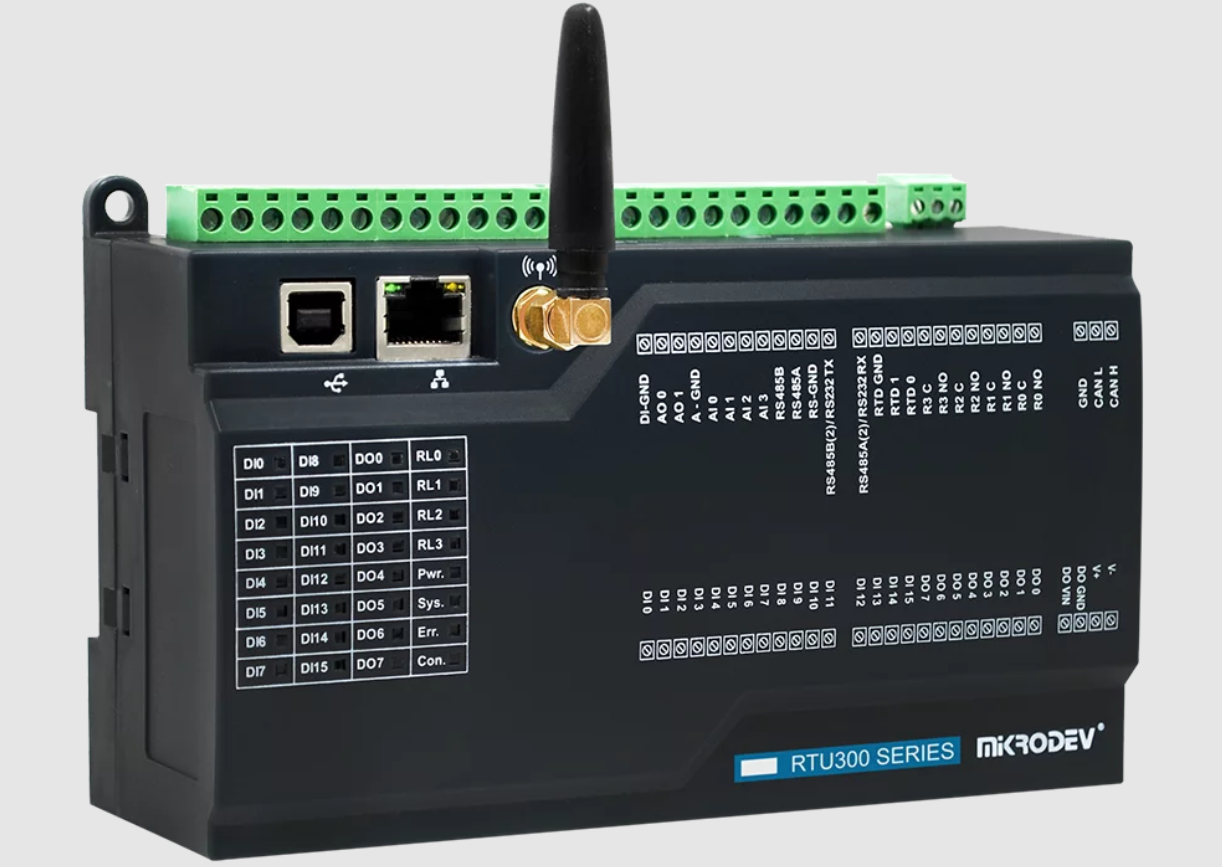

Did You See Mikrodev’s RTU Devices?

Catch the industrial automation revolution now with Mikrodev’s Industrial RTU Routers, DM100 RTU Devices, Rack Type Remote Terminal Unit RTUs and RTU300 Devices! Take a look at our product pages to discover Mikrodev’s revolutionary RTU solutions!

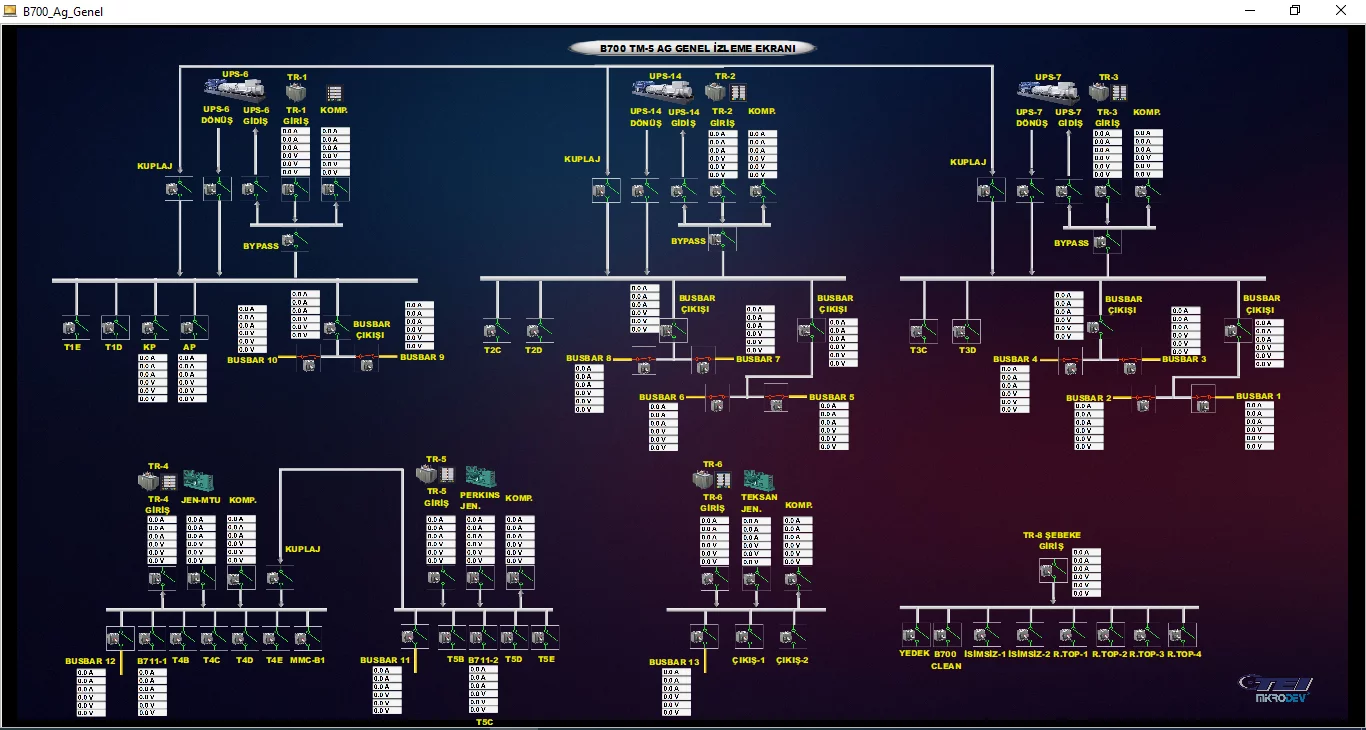

What is SCADA RTU?

SCADA (Supervisory Control and Data Acquisition) is a software used in industrial automation systems frequently integrated with RTU devices. RTU devices collect data from sensors and transfer this data to SCADA software. SCADA collects data from the field via RTU units and monitors it at a central control point. This collaboration ensures effective management of industrial processes.

What is RTU Programming?

Terminal units need to be programmed correctly and efficiently to function properly. Programming determines how remote terminal units react to field devices, what data they collect, and how they transmit it. The functionality of remote terminal units is also increased through RTU programming and RTU control. RTU programming also enables remote terminal units to collect data from sensors and share this data with a central control system. In this context, RTU programming can be referred to as the heart of industrial automation.

In Which Areas Are Remote Terminal Units Used?

As mentioned throughout our article, remote terminal units are widely used in industrial automation systems. These remote units are used in many industrial applications, from water treatment plants to power plants, oil and gas pipelines, and traffic management systems. These applications include energy systems, clean water, wastewater and sewage, wastewater recycling, oil and gas, mining, food and beverage, chemical and petrochemical, automotive, textile, and many other industries. In summary, remote terminals can be used effectively anywhere remote monitoring and control is required.

What are the Differences Between RTU and PLC?

RTUs (Remote Terminal Units) and Programmable Logic Controllers (PLC)

are two critical components of industrial automation, but they have different tasks. As mentioned in our previous articles, a PLC is a local process controller, while an RTU terminal is optimized for remote data acquisition and transmission, as discussed above. PLCs are also easier to program and have fewer input/output points. RTU units, on the other hand, are designed to control more complex systems and have a more significant number of input/output points. Simply put, RTU remote terminals are intended to communicate with remote field devices, while PLC devices usually handle local control of a plant. Plus, it’s possible to perform remote control with PLCs. PLCs have features that allow remote access via the Internet or other communication protocols.

Manage the Future of Industrial Automation with Mikrodev’s RTU Devices!

Mikrodev offers RTU units and devices with advanced technology for industrial automation. With the DM100 Series RTU (Remote Terminal Unit), RTU100 Series RTU (Remote Terminal Unit), and RTU300 Series RTU (Remote Terminal Unit) product family under the Distributed Control System (DCS), Mikrodev provides reliability and functionality to automation systems. These devices offer excellent solutions to industries for data acquisition, remote monitoring, and control applications in industrial plants.

As a result, RTU units, or in other terms, remote terminals, RTU terminals, and RTU controls, are an integral part of industrial automation and are used effectively in many sectors. Mikrodev’s indigenous RTU devices are an indispensable component in increasing the efficiency and reliability of industrial processes. Mikrodev RTU systems support businesses to make more intelligent and more efficient decisions by providing reliable collection and monitoring of data from the field.

Mikrodev is an IT, software, electronics industry, and trade company established in Istanbul in 2006. An important step was taken by adding RTU (Remote Terminal Unit) devices to the company’s product family in 2013. With its expert staff, Mikrodev continues its R&D activities in the Bilişim Vadisi and Kocaeli/Çayırova facilities. Our brand continues to produce more than 200 types of devices, including but not limited to Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), Expansion Modules, IoT Protocol Converters, Operator Control & Monitoring Systems (SCADA) product families. Mikrodev, as a company that supports national production in the industrial automation sector in Turkey, aims to assume a leading role in the industrial automation sector with its vital technical infrastructure, innovation-oriented vision, flexible solutions, and customer-oriented approach. For the current remote terminal unit prices, please get in touch with our experts!