What Is RTU Device?

RTUs (Remote Terminal Units) are important components used in industrial automation systems. These devices communicate with field devices (sensors, actuators, switches, etc.) and collect, process, store, and/or control the data from these devices. They are typically in communication with a control room or a central system and are used to monitor and control physical processes in the field.

RTUs are designed for use in complex systems in industrial facilities, often found in areas such as power distribution, water treatment, and oil and gas production. They gather and process data from sensors in these facilities, which typically include process parameters such as temperature, pressure, flow rate, and level. Additionally, RTUs can transmit commands to control devices in the field, providing automation and remote control capabilities.

RTUs are designed for use in complex systems in industrial facilities, often found in areas such as power distribution, water treatment, and oil and gas production. They gather and process data from sensors in these facilities, which typically include process parameters such as temperature, pressure, flow rate, and level. Additionally, RTUs can transmit commands to control devices in the field, providing automation and remote control capabilities.

RTUs typically support many industry standards and can perform protocol conversions between different communication protocols. They can be compatible with common industrial communication protocols such as Modbus, Profibus, and DNP3. Additionally, they can utilize Ethernet, serial communication (such as RS-232, RS-485), and wireless communication technologies.

RTUs are usually designed to operate in rugged and industrial environments. These devices often need to operate continuously for long periods and must be resistant to various environmental conditions (temperature, humidity, dust, vibration, etc.).

In conclusion, RTUs play a critical role in industrial automation systems as they are necessary for the collection, processing, and control of data in the field. These devices are important tools for improving the efficiency of industrial facilities, reducing operational costs, and ensuring security.

What Is the Purpose of an RTU Device?

An RTU (Remote Terminal Unit) is a device that plays a significant role in industrial automation systems. Its functions include:

- Data Collection

- Data Processing

- Control

- Monitoring and Diagnostics

- Data Storage

- Remote Access and Control

RTUs serve as crucial components in industrial automation systems, communicating with sensors, actuators, and other devices at the field level and collecting data from these devices. They process and analyze the collected data and, when necessary, transmit control commands to field devices, enabling process control. Thus, they enable monitoring, control, and data collection of processes in industrial facilities.

RTUs also monitor the status of devices in the field and diagnose issues, enhancing operational efficiency and facilitating troubleshooting processes. Additionally, they store collected data, providing access to historical data for future analysis. Designed to operate in durable and industrial environments, RTUs allow experts to access facilities remotely, even from distant locations, due to their remote access capabilities.

In summary, RTUs play a critical role in the automation processes of industrial facilities. By performing functions such as monitoring, control, data collection, and analysis, they enhance efficiency, reduce operational costs, and ensure security. Therefore, they are considered indispensable components of industrial automation systems.

What Is SCADA RTU?

SCADA (Supervisory Control and Data Acquisition) is a control system used to monitor, control, and collect data from processes in industrial facilities. SCADA systems are typically managed by a control room or a central system and perform functions such as real-time data collection, monitoring, control, and reporting by communicating with field devices.

RTUs (Remote Terminal Units), on the other hand, are components of SCADA systems at the field level. RTUs communicate with sensors, actuators, switches, and other devices in the field, collecting data from these devices. They process the collected data and transmit it to the SCADA system, as well as being able to transfer control commands from the SCADA system to field devices.

In essence, the SCADA RTU combination is a system that collaborates to monitor, control, and collect data from processes in industrial facilities. While the SCADA system provides centralized control, RTUs communicate with field devices to execute this control. This integrated system is used to enhance the efficiency of industrial facilities, reduce operational costs, and ensure security.

Final Thoughts

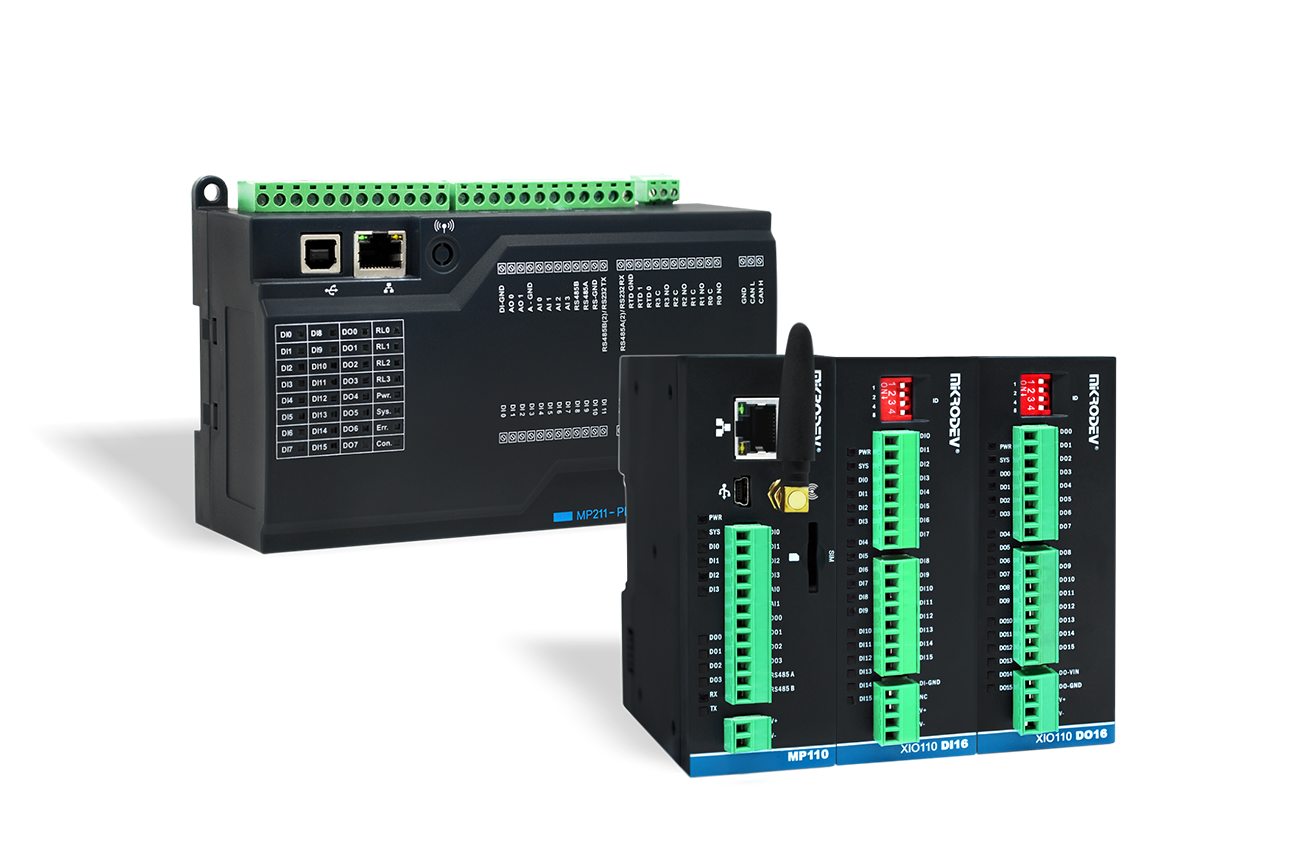

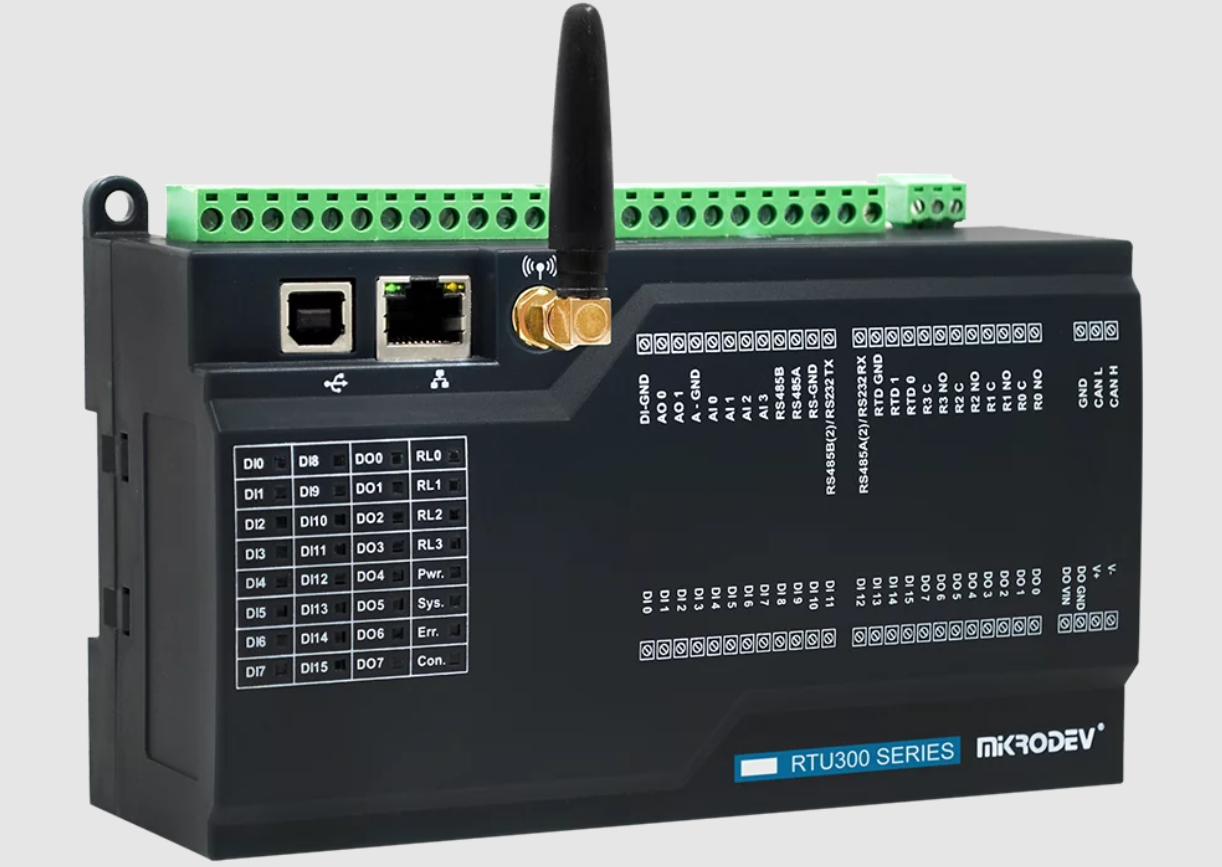

In industrial automation systems, RTUs (Remote Terminal Units) perform critical tasks such as monitoring, control, and data collection of processes. Products such as Mikrodev’s DM100 Series RTU, DM50 Series RTU Router, DM500 Series RTU, RTU100 Series RTU, and RTU300 Series RTU offer reliable and effective remote terminal unit solutions for industrial facilities. With their durable designs, compatibility with various communication protocols, and remote access capabilities, these products are ideal for meeting industrial automation needs.

For more information on Mikrodev’s RTU solutions and to view the products, you can visit the following link: Mikrodev RTU Products.