What is SCADA, Who Uses It and How It Works

What is SCADA?

SCADA refers to a system that collects data from various sensors at a factory, plant, or in other remote locations and then sends this data to a central computer which manages and controls the data. These systems are used to monitor and control a plant or equipment in industries such as telecommunications, water and waste control, energy, oil and gas refining, and transportation.

What does SCADA stand for?

SCADA stands for Supervisory Control and Data Acquisition. It refers to a system that oversees industrial processes, controls equipment, and gathers data from sensors and devices. This centralized system allows operators to monitor, manage, and optimize industrial operations efficiently.

Where Are SCADA Systems Used?

SCADA systems are used across a wide range of industries and applications, including:

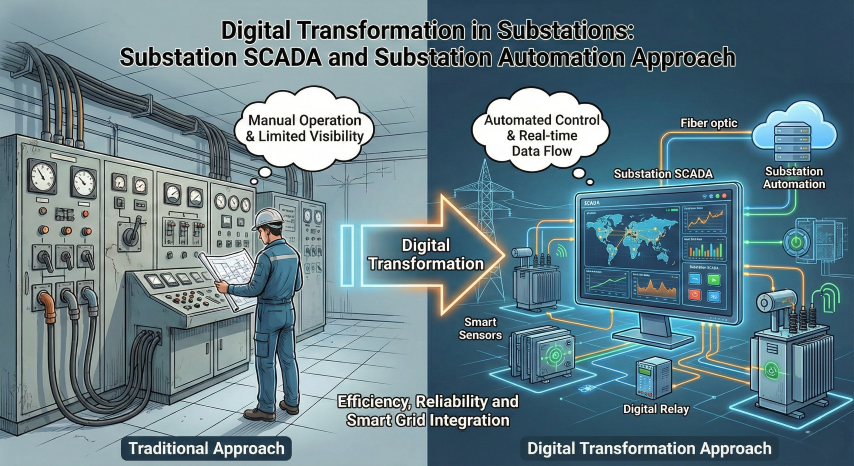

- Energy Management: Monitoring and controlling electricity generation and distribution, including power plants, substations, and renewable energy sources such as solar and wind farms.

- Water Management: Overseeing water distribution networks, wastewater treatment plants, reservoirs, and pumping stations for efficient water management and conservation.

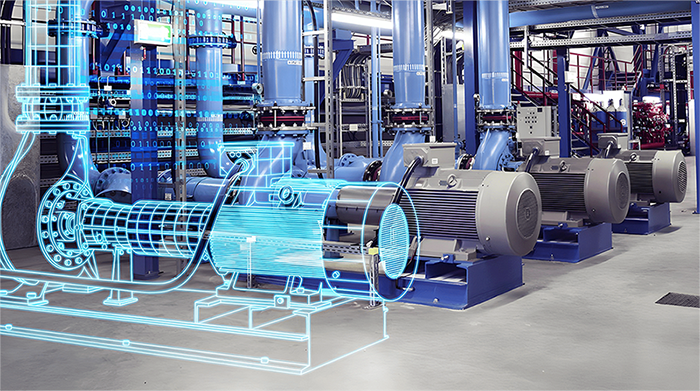

- Manufacturing: Managing production processes, quality control, inventory management, and equipment monitoring in industries such as automotive, pharmaceuticals, food and beverage, and electronics manufacturing.

- Transportation: Monitoring and managing traffic flow, railway systems, airports, seaports, and public transit systems for improved safety, efficiency, and passenger experience.

- Oil and Gas Industries: Controlling pipeline networks, refinery operations, offshore platforms, and distribution terminals for safe and efficient extraction, processing, and transportation of oil and gas resources.

- Building Automation: Controlling and optimizing building systems such as HVAC, lighting, security, and access control to improve energy efficiency, occupant comfort, and safety.

- Environmental Monitoring: Collecting and analyzing data on air quality, pollution levels, weather conditions, and environmental parameters to support environmental protection and regulatory compliance efforts.

How Does SCADA Operate?

SCADA operates as a comprehensive system for monitoring, controlling, and optimizing industrial processes, providing operators with real-time visibility and control over critical assets and infrastructure.

SCADA operates through a systematic process that involves several key steps. Firstly, data acquisition occurs, where sensors and instruments collect data on various parameters like temperature, pressure, flow rate, and voltage. These sensors are typically connected to Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs), which convert analog signals from the sensors into digital data.

Following data acquisition, the digital data is transmitted to a central supervisory system via communication networks. These networks may include wired connections such as Ethernet or serial cables, as well as wireless technologies like radio, cellular, or satellite communication. Once the supervisory system receives the data from the field devices, it processes it using specialized software.

Data processing tasks include data logging, trend analysis, alarm detection, and computation of key performance indicators (KPIs). The processed data is then stored in a database for further analysis and reporting. Subsequently, the processed data is presented to operators in a user-friendly format through a Human-Machine Interface (HMI).

The HMI typically includes graphical displays, charts, alarms, and controls that allow operators to monitor the status of industrial processes and equipment in real-time. Based on the information displayed on the HMI, operators can take appropriate actions to control the industrial processes and equipment. This may involve adjusting setpoints, opening or closing valves, starting or stopping pumps, or initiating emergency shutdown procedures.

Operators can also monitor the performance of the system and respond to alarms or alerts as needed. Furthermore, SCADA systems store historical data collected over time, enabling trend analysis, performance evaluation, and predictive maintenance. Advanced analytics tools can identify patterns, anomalies, and opportunities for optimization, facilitating continuous improvement of industrial operations.

What format is SCADA data?

SCADA data can be stored in various formats including time-series data, CSV, database formats like MySQL, PostgreSQL, or SQL Server, binary formats, and JSON/XML. SCADA systems may also use proprietary historian databases. Each format has its own advantages and suitability depending on system requirements and user preferences.

What Does SCADA Measure?

SCADA systems measure a wide range of parameters critical to industrial processes, including temperature, pressure, flow rate, level, voltage, current, speed, position, quality, environmental conditions, and alarm conditions. These measurements are essential for monitoring the performance and status of industrial equipment and processes in real-time. By collecting and analyzing data on these parameters, SCADA systems enable operators to make informed decisions, detect abnormalities, and respond promptly to changes or faults, thereby ensuring efficient and safe operation of industrial facilities.

What Are The Advantages of the SCADA System?

- Real-time Monitoring: SCADA systems provide real-time monitoring of industrial processes and equipment, allowing operators to stay informed about system status and performance.

- Remote Control: Operators can remotely control processes and equipment through SCADA systems, reducing the need for manual intervention and improving operational efficiency.

- Data Collection and Analysis: SCADA systems collect data from sensors and devices, enabling analysis of trends, patterns, and performance metrics. This data-driven approach supports informed decision-making and optimization of processes.

- Improved Efficiency: Automation and optimization features of SCADA systems help improve efficiency by reducing downtime, minimizing waste, and optimizing resource utilization.

- Enhanced Safety: SCADA systems enable early detection of anomalies, faults, and hazardous conditions, allowing operators to take timely action to prevent accidents and ensure a safe working environment.

- Remote Access: SCADA systems can be accessed remotely via secure connections, allowing operators to monitor and control industrial processes from anywhere with an internet connection.

- Scalability and Flexibility: SCADA systems are scalable and adaptable to the changing needs of industrial operations, allowing for easy integration of new equipment, processes, and technologies.

- Regulatory Compliance: SCADA systems help ensure regulatory compliance by providing accurate data logging, reporting, and documentation of industrial processes and operations.

- Cost Savings: By optimizing processes, reducing downtime, and improving efficiency, SCADA systems can lead to significant cost savings for industrial organizations over time.

How Can Mikrodev Help Me About SCADA?

Mikrodev can assist you with SCADA (Supervisory Control and Data Acquisition) solutions in several ways. Firstly, Mikrodev offers customizable SCADA software that can be tailored to meet the specific needs of your industrial processes and applications. This software provides real-time monitoring, control, and data acquisition capabilities, allowing you to oversee and manage your operations efficiently. Additionally, Mikrodev offers hardware solutions such as Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) that seamlessly integrate with their SCADA software, ensuring reliable data collection and control of industrial equipment. Furthermore, Mikrodev provides comprehensive support services, including installation, training, and ongoing technical assistance, to ensure that your SCADA system operates smoothly and effectively. Overall, Mikrodev’s expertise and technology can empower you to optimize your industrial processes, improve productivity, and enhance operational efficiency with robust SCADA solutions tailored to your specific requirements.