Arçelik strengthened its motion control system to enhance the quality of remote controls for televisions by opting for Mikrodev products in the TV remote control functional test system. Utilizing the MP110 series Mikrodev PLC and Viewsmart Mikrodev SCADA products, a 3-axis movable test system was developed, enabling continuous recording of the performance outputs of the remote control at various distances and angles.

Arçelik, a leading manufacturer of robust household appliances and white goods in the global market, utilized the MP110 series Mikrodev PLC and Viewsmart Mikrodev SCADA products to develop a 3-axis movable test system aimed at enhancing the quality of remote controls for televisions. Through the developed motion control system, performance outputs of the remote control at different distances and angles are continuously recorded without interruption.

In a project highlighted as an application example of a motion control system with PLC, Arçelik conducts the functional tests of remote controls produced in serial production with a motion test system established using Mikrodev PLCs.

Within the scope of the project:

- A mechanical system capable of moving in 3 axes is controlled with Mikrodev MP110 series PLC products.

- The angular control of the panel where the remote control is positioned is managed with the PTO outputs of MP110 series products.

- Servo and stepper motor controls are performed with MP100 series PLCs.

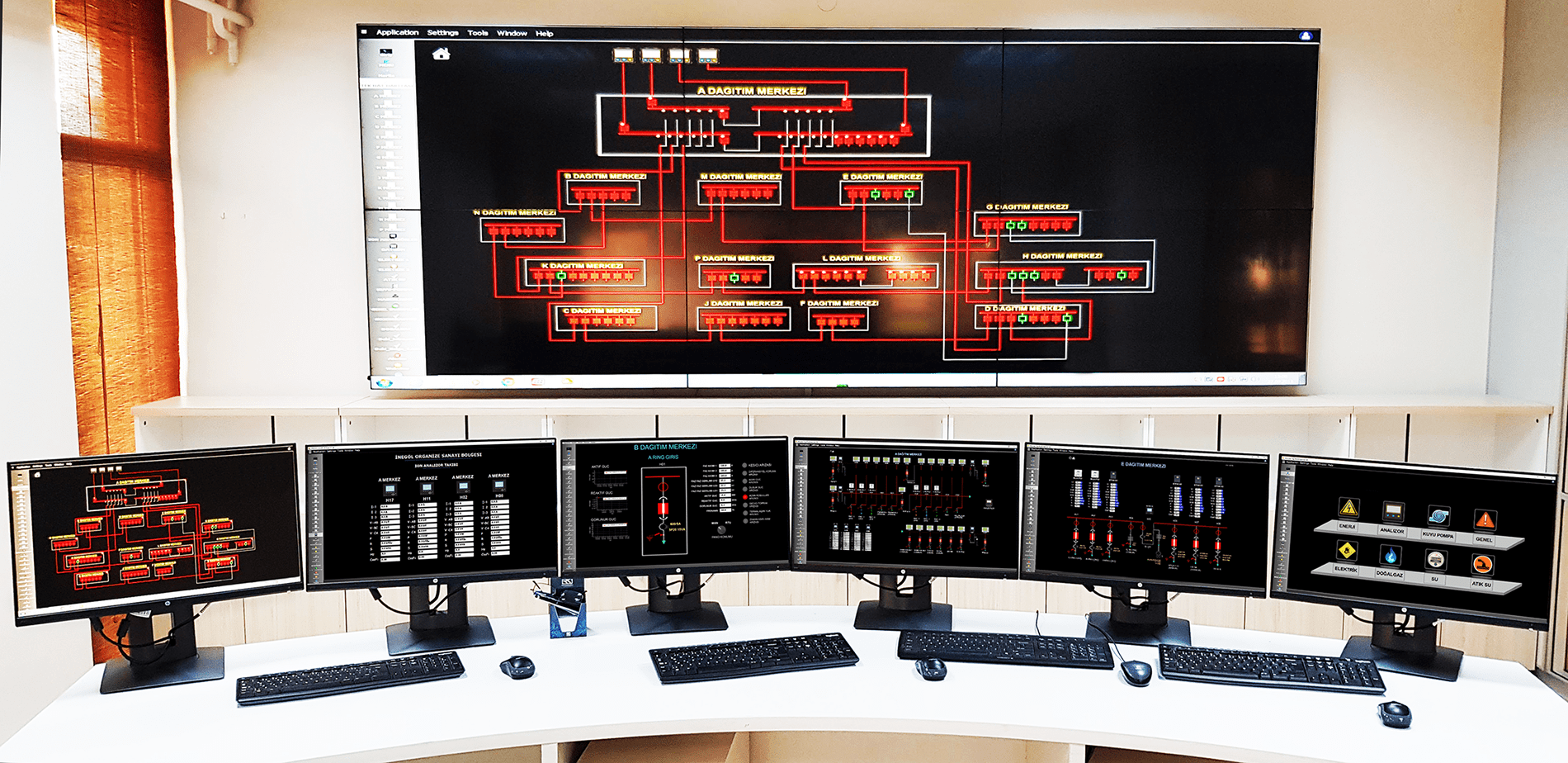

- The coordinates at which the movable unit will stop are managed with ViewPlus SCADA software.

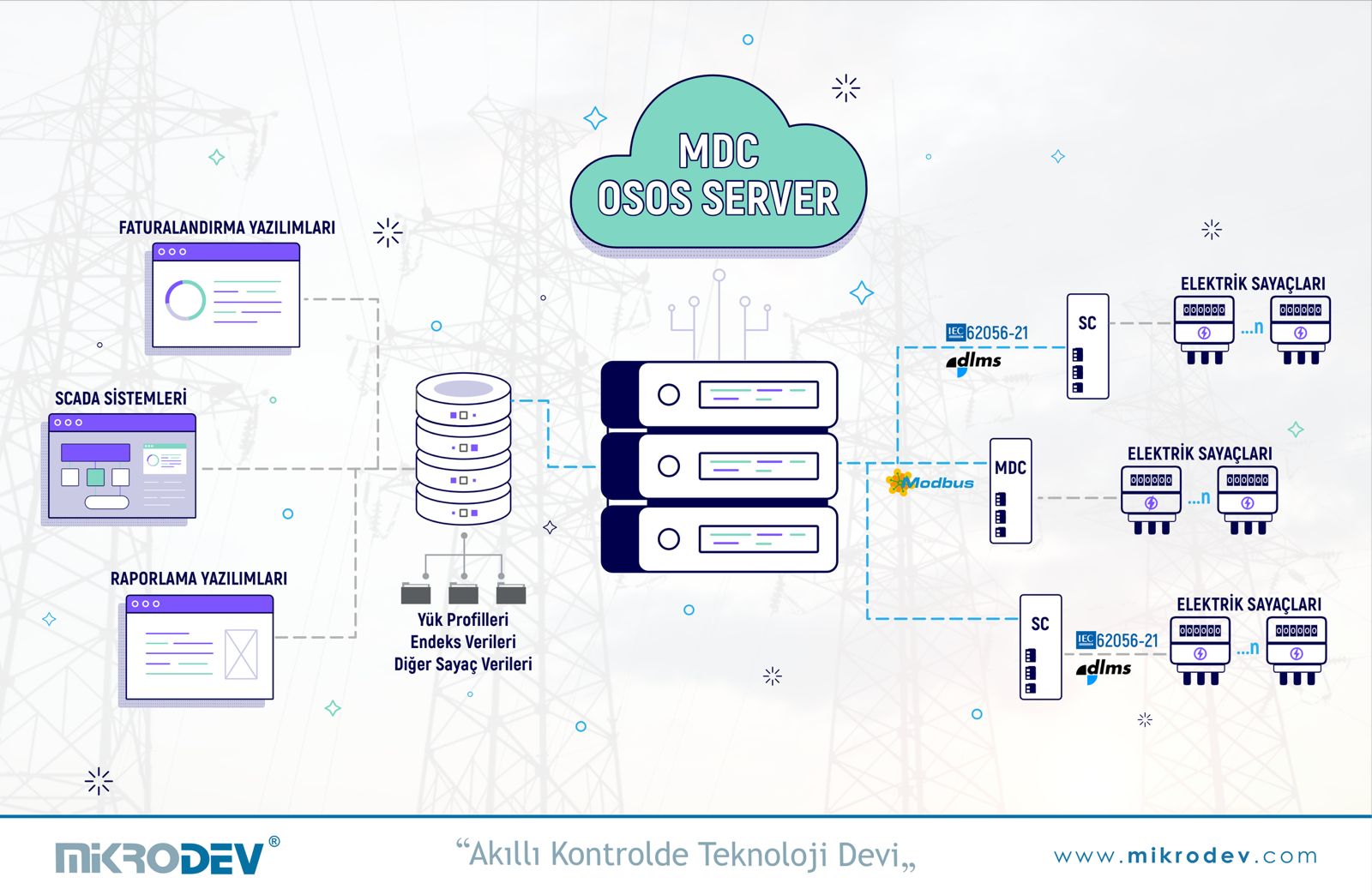

Mikrodev’s product range of MP110 Series PLCs, utilized in the project for motion control functions, enable complete system control via ViewPlus SCADA software on tablets or PCs.

Thanks to the test system established via Mikrodev PLC and SCADA software:

- Functional tests of produced remote controls can be conducted with higher precision.

- Production times are optimized.

- The serial production error rate is reduced.

- More meaningful and detailed test outputs can be generated for the Arçelik R&D team.

- Prototype test times are reduced, optimizing product development cycles.

Mikrodev’s product range of MP110 Series PLCs successfully perform motion control functions in this project, enabling complete system control via ViewPlus SCADA software on tablets or PCs. This integrated system allows for more precise functional testing of produced remote controls, reduction of the serial production error rate, optimization of production times, and obtaining more meaningful and detailed test outputs for the Arçelik R&D team.

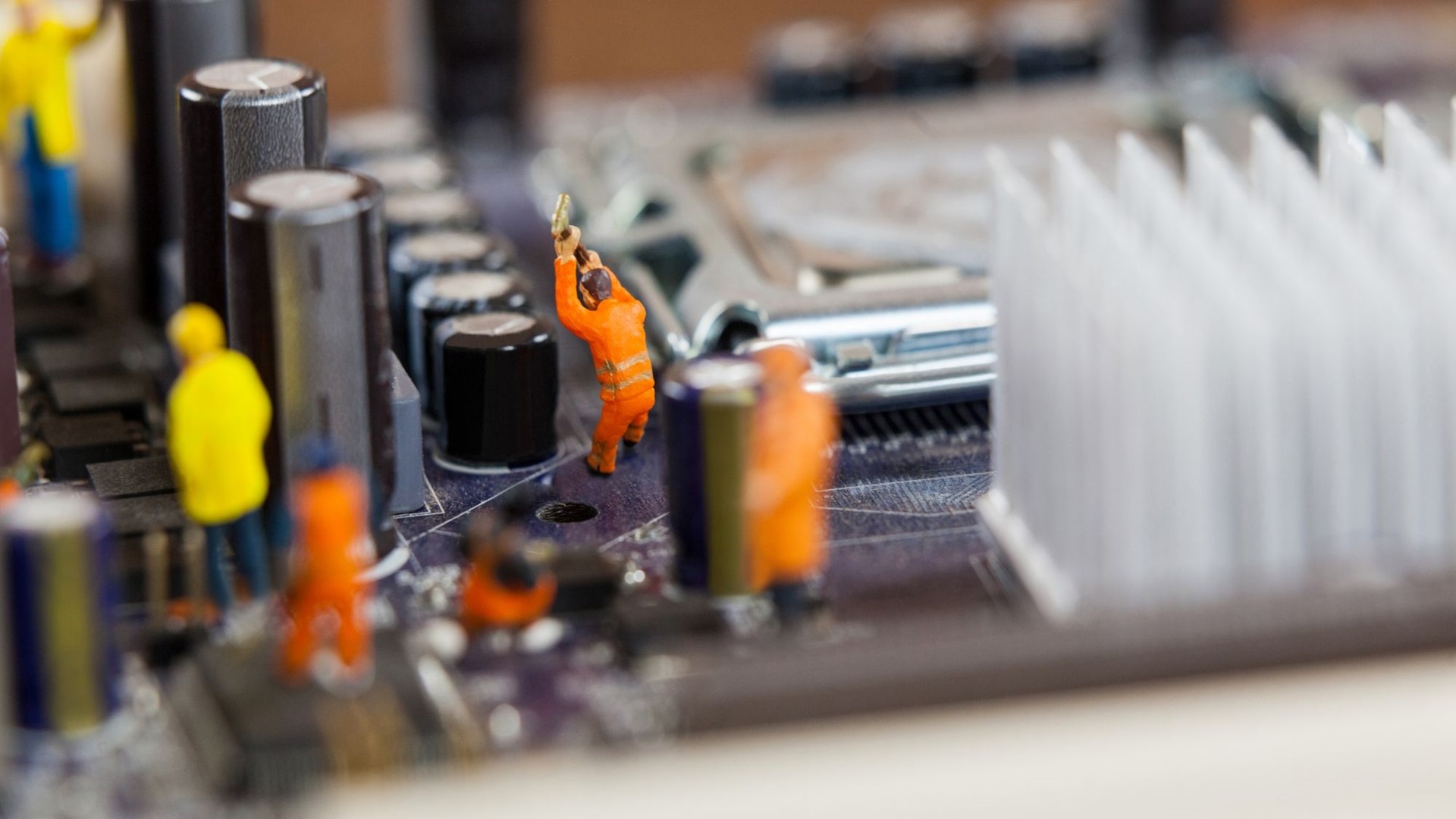

Explore images related to the project in our gallery, and experience the difference of Mikrodev in Arçelik TV remote control production by watching our videos.

As a pioneer in automation technologies and automation products, Mikrodev continues to support its partners in various fields of industrial automation with new projects.

You can contact our experts for Mikrodev’s solutions in various automation fields and products including production of PLCs, RTUs, and SCADA devices.