Distributed Control System (DCS) is an automation system and is used to control a manufacturing facility or an industrial process. These systems work in connection with each other by communicating many different control elements with each other. For example, a DCS system can control the speed of a pump or the opening and closing of a valve by helping to measure the pressure, temperature, and flow rate of a process. In this way, it can be followed by a large number of different parameters to optimize the performance of a process and prevent errors.

Distributed Control System (DCS) products come to the fore with the management of smart devices used by almost everyone today. In extensive and complex industrial processes, it can be observed how effective distributed control systems are compared to older central control systems. That is, unlike a centralized control system that runs all machines, a DCS ensures that each part of a machine has its own dedicated controller that performs the operation. In this sense, it can also be called a digital automated industrial control system that uses geographically distributed control loops throughout a factory, machine or control area. The task of distributed control systems can be described as the process of automatic control of facilities or industrial processes. Distributed control system architecture provides more lucrative ways to improve the reliability of control, process quality and plant efficiency.

Why Is It Important to Use a Distributed Control System (DCS)?

The Distributed Control System (DCS) is important for automatic control of a process. These systems help manage processes more efficiently and reduce errors. Thanks to this, production costs are reduced and production capacity increases.

DCS systems also ensure the security of a process. For example, if the pressure or temperature of a process rises above a certain level, the DCS system can automatically stop the process and prevent damage.

Besides this, DCS systems also increase the efficiency of a process. For example, keeping the temperature and pressure of a process at the right levels allows the process to run more efficiently. Thanks to this, production costs are reduced and production capacity increases.

As a result, the Distributed Control System (DCS) is important for automating the control of a process, ensuring its security and increasing its efficiency.

What are Mikrodev Distributed Control Systems (DCS) Product Groups?

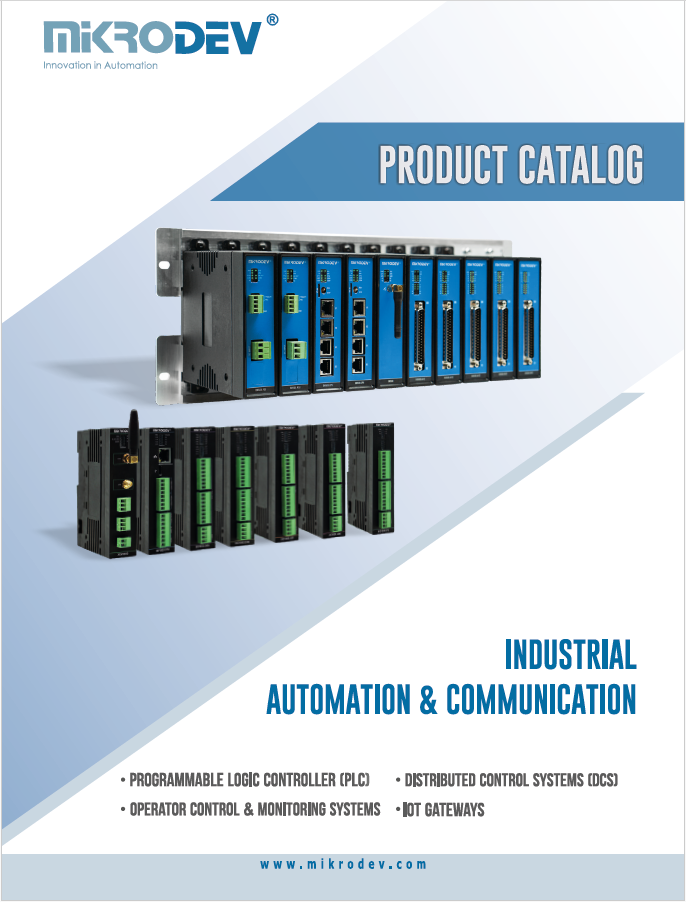

Mikrodev Distributed Control Systems (DCS) product groups and order codes are listed as follows:

- DM50 Series RTU Router (Industrial RTU Router): (DM50-E1LW-GE0-B7008)

- DM100 Series RTU (Remote Terminal Unit): (DM100-E1N-GC0-B1000 and DM100-E2N-GC3-B1000)

- DM500 Series RTU (Rack Type Remote Terminal Unit): (DM500-E0-BP0-B0000, DM500-E0-IO0-B2000, DM500-E0-IO1-B2000, DM500-E0-IO2-B2000, DM500-E0-IO3-B2000, DM500-E0-PS0-B0000, DM500-E0-PS1-B0000, DM500-E0N-CM0-B0000, DM500-E0N-CM1-B0000 and DM500-E2-CP0-B1000)

- RTU300 Series RTU (Remote Terminal Unit): please visit our category page. You can review the detailed technical specifications of the products in all models on the specific product page and you can also download them as files by creating specification specific PDFs.

What Industries Are Distributed Control Systems Used?

Distributed Control System (DCS) is actively used in a large number of industries nowadays. Distributed Control Systems (DCS), especially in areas such as oil, petrochemical and gas industries, refineries, chemical plants, power generation, mining, food and beverage processing plants, chemical plants, nuclear power plants, water management and treatment systems, sewage treatment plants, automobile industry, forest products, agriculture and fertilizer sector and pharmaceutical manufacturing systems are widely used. In addition, the use of DCS in continuous production processes is also becoming widespread.

Reliable Distributed Control System (DCS) Devices with Mikrodev Warranty!

Mikrodev, which is among the pioneers of the sector by producing domestic industrial control and communication products from 2006 to today, adopts a customer-oriented approach with its registered trademark, strong technical infrastructure and adaptive solutions. Our company, which has realized its steady growth and development from its establishment to date, has signed more than 200 models of PLC, RTU, IoT Gateway, Industrial Router, HMI and SCADA software products. In this context, Mikrodev is an innovative and visionary manufacturer of the sector in the fields of industrial automation and telemetry. Mikrodev brand, which exports to 20 countries as of 2022, continues its investments in research and development activities in the TÜBİTAK R&D center and IT Valley R&D center in Turkey. Mikrodev, your trusted brand in the industry for Distributed Control System (DCS) products!