Risks in Operational Technology (OT) are growing, and errors are turning into downtime and costs. IEC 62443 is a family of role- and process-oriented standards recognized as the reference for cybersecurity in industrial control systems. It covers PLC and SCADA layers, networks, suppliers, and operational processes, offering clear requirements to achieve a manageable security level.

This guide proceeds step-by-step according to real needs in the field. It begins with asset inventory and risk analysis, then moves on to concrete steps such as network segmentation, firewall policies, secure configuration, patch management, monitoring, and incident response. In the final section, you will find a short roadmap for the evidence and practices required for auditing and certification.

PLC security requires controlling device integrity, unauthorized commands, and software changes. SCADA security revolves around user access, protocol hardening, session logging, and data integrity. OT security manages both areas, along with field networks and IT integration points, demanding an end-to-end approach, not just a single product focus.

Cyber threats are now targeted and persistent, confronting us on a wide front from the supply chain to remote access. IEC 62443 provides a common language and control set to systematically reduce these risks. If you want a deeper look at SCADA-side risks, check out this resource: Cybersecurity of SCADA systems.

In the following sections, we will explain each step with simple checklists and brief examples. Our goal is to provide a roadmap that your teams can start implementing today, accelerating IEC 62443 compliance and securing business continuity. This way, your PLC security and SCADA security investments produce measurable results.

Discover the Fundamental Concepts of the IEC 62443 Standard

IEC 62443 offers a clear structure for OT security. The standard defines requirements at the organization, system, and component levels. This allows you to manage PLC security and SCADA security goals in a measurable way. The structure below clarifies where to start the implementation and prepares the ground for the certification path.

What are the Main Components of IEC 62443?

In practice, IEC 62443 is addressed in three layers:

-

IACS (Industrial Automation and Control System) Processes (Part 2-1, 2-4): Policy, risk, procurement, and operation processes. Examples: Asset inventory, authorization matrix, patching policy, supplier security requirements.

-

System Security (Part 3-2, 3-3): Architecture and network level controls. Examples: Network segmentation, firewall rules, secure remote access, monitoring, and logging.

-

Component Security (Part 4-1, 4-2): Product and device hardening. Examples: Secure boot for PLCs, signed firmware, disabling SCADA services, strong authentication.

This structure connects to four main functions:

-

Identification: Asset inventory, network map, security levels. Device and firmware list in PLCs, user and role inventory in SCADA.

-

Protection: Access control, hardening, network segmentation, firewall. Example: DMZ for the production cell, rule-based restriction on PLC programming ports.

-

Detection: Logs, anomaly detection, change monitoring. Example: SCADA session logs and PLC configuration change alerts.

-

Response: Incident plan, backup, recovery tests. Example: Putting the PLC into a safe state after detecting a malicious command, restoring from a known good image.

A set of evidence is required for certification: risk analysis, policy and procedures, test reports, audit trails. Product and system verification are conducted by independent bodies.

Why is This Standard Necessary for PLC and SCADA?

Industrial systems are vulnerable to targeted attacks. In past incidents, fake commands changed PLC logic, causing equipment damage. On the SCADA side, weak passwords, faulty remote access, and unpatched services stopped production or led to data leakage. These impacts turned into significant costs within hours.

IEC 62443 provides a common language for PLC security and SCADA security. It links OT security requirements to processes. In the short term, it reduces the risk and attack surface; in the long term, it strengthens operational continuity.

-

Less downtime: The spread area is narrowed with network segmentation and firewalls.

-

Lower costs: Incident response and backup are planned, reducing loss and repair.

-

Compliance and certification: Audit trails are ready, and supply chain expectations are met.

The conclusion is clear: the standard makes systems more secure and accelerates the compliance process. This framework allows teams to work focused and helps investments produce measurable results.

Step-by-Step IEC 62443 Implementation for PLC and SCADA

IEC 62443 offers a practical roadmap for OT security. The following steps make PLC security and SCADA security processes regular, measurable, and auditable. First, we clarify the risks, then we organize the architecture, implement controls, monitor and improve, and finally complete the evidence with certification.

Step 1: Assess and Define Risks

The starting point is a comprehensive asset inventory. Every item, including PLCs, RTUs, HMIs, SCADA servers, network switches, routers, firewall devices, and service accounts in the field, must be clearly listed. Record the hardware model, firmware version, IP address, location, function, and critical impact information.

Threat modeling reveals which vectors are more probable and effective. A simple approach:

-

Classify threat types with STRIDE or attack trees.

-

Reference MITRE ATT&CK for ICS tactics.

-

Score the results in a probability and impact matrix.

-

Map the “zone and conduit” concepts in IEC 62443 to appropriate security levels.

Specific risks for PLC and SCADA:

-

PLC risks: Exposed programming ports, unsigned firmware, default passwords, unauthorized ladder logic changes, insecure services (TFTP, SMB), physical access.

-

SCADA risks: Shared accounts, weak password policy, lack of session monitoring, unencrypted protocols (Modbus/TCP), misconfigured OPC UA, weak VPN policies for remote access.

-

Integration risks: IT-OT bridge, backup shares, vendor connections, poor segmentation.

Benefit: This step sets a measurable target security level and clarifies investment priorities.

Tool suggestions (without promoting sales or products):

-

Inventory: Rumble or Open-AudIT, verification of ports and services with Nmap.

-

Passive discovery and protocol analysis: Zeek, Wireshark.

-

Configuration and change tracking: Git-based configuration versioning, syslog collection.

-

Documentation: CMDB, network diagram, zone-conduit schemes.

For additional framework information, you can reference a summary introduction page to the IEC 62443 clauses that provide an overview.

Step 2: Isolate with Network Segmentation

Network segmentation effectively reduces risk. The goal is to put assets with the same risk level into a “zone” and carry the data flow between them in a controlled manner via a “conduit”. Production cells, SCADA servers, DMZ, remote maintenance area, and the corporate network should be separate segments.

How to implement:

-

Separate all critical assets into production cells, restrict direct access within the cell.

-

Keep SCADA servers in a separate management VLAN, give controlled access to workstations and the historian.

-

Establish a DMZ between IT-OT, perform data transfer with a one-way gateway or intermediary services.

-

Manage maintenance and engineering stations with a temporary access model, remove permanent connections.

Examples of separating PLC and SCADA traffic:

-

Modbus/TCP (502) should only go to PLCs from specific SCADA IPs.

-

TLS and secure user modes must be mandatory for OPC UA (4840).

-

DNP3 (20000) and IEC 60870-5-104 (2404) should only be open between defined stations.

-

Management services like SMB, RDP, SSH should only be open to allowed sources from the management segment.

Firewall integration:

-

Use stateful rules on every conduit, apply an “allow list” approach.

-

Apply strict restriction based on direction and port, set the default to “deny”.

-

Verify OT protocols with application-aware rules.

-

Send logs to a central SIEM.

Benefit: Prevents attack spread, limits incidents within the cell, shortens recovery time. If you want additional reading on SCADA practices, this guide is useful: SCADA system security best practices.

Step 3: Implement Access Controls and Firewalls

Access must be limited according to the task and context. IEC 62443 prioritizes role-based authorization and the principle of least privilege.

Role-based access and MFA:

-

Roles: Operator, engineer, maintenance, vendor, auditor.

-

Create an authorization matrix for each role, document it.

-

Use Multi-Factor Authentication (MFA), especially for SCADA servers, management stations, and VPN access.

-

Eliminate shared accounts, link all sessions to a specific user.

-

Implement a time-limited, approved, and logged temporary access model.

-

Define a “break-glass” emergency access account, keep it secured, and log its usage.

Firewall setup steps with a simple checklist:

-

Create an asset and flow list, map it at the source-destination-port level.

-

Define flows to be allowed one by one, block the remaining traffic.

-

Manage management plane traffic (RDP, SSH, SNMP) in a separate list.

-

If deep packet inspection is available for ICS protocols, enable it.

-

Centralize logs for instant alerts and weekly review.

-

Implement change management and the two-person rule for rule changes.

Tips for SCADA protocols:

-

Monitor function codes for Modbus/TCP, open write commands only during scheduled maintenance hours.

-

Select a secure policy in OPC UA, close anonymous access, regularly perform certificate management.

-

Allow only expected station pairs in DNP3 and IEC 104 flows, prevent line routing.

-

Provide NTP for time synchronization from secure sources, do not leave it open to the outside world.

Benefit: Reduces erroneous access, prevents privilege misuse, and shrinks the attack surface with granular firewall rules.

Step 4: Ensure Monitoring and Maintenance

Continuous monitoring is the living part of IEC 62443 compliance. You generate early warnings through anomaly detection, configuration change tracking, and log collection.

Continuous monitoring tools and practices:

-

Use passive monitoring and protocol analysis for OT traffic.

-

Send SCADA, historian, and engineering station logs to a SIEM.

-

Record PLC configuration changes and firmware updates.

-

Monitor HMI and SCADA server files with File Integrity Monitoring (FIM).

-

Define clear thresholds and notification channels for critical alarms.

Updates and training:

-

Link patch management to maintenance windows, test first in a test cell.

-

Regularly take configuration backups, plan recovery tests.

-

Repeat operator and engineer training in short modules, include social engineering scenarios.

-

Review vendor access processes at least once a year.

Certification link:

-

Monitoring logs, test outputs, inventory, and policy documents form the evidence set in the certification process.

-

Annual internal audits facilitate closing gaps before external audits.

Benefit: You catch incidents early, MTTR (Mean Time To Recovery) drops, and evidence is generated regularly.

Step 5: Perform Certification and Compliance Tests

Certification confirms the discipline and maturity of the process through an external eye. The goal is to prove and sustain the security levels defined according to IEC 62443.

Summary steps:

-

Gap analysis: Compare your current state with standard requirements.

-

Corrective action: Close policy, architecture, and control deficiencies.

-

Internal testing and verification: Penetration testing, configuration review, recovery practice from backups.

-

Documentation: Risk analysis, inventory, network diagrams, procedures, test reports, log samples.

-

Independent audit and certification: Conduct the audit with an authorized body, close findings.

Independent audits:

-

The scope is defined at the system and component level.

-

Sample audits and field observations are performed.

-

Evidence is checked with logs and change records.

Success metrics should be tracked with numbers:

-

Inventory coverage should be close to 100%.

-

Segmentation coverage should include 100% of critical cells.

-

MFA coverage should aim for 100% for management and SCADA users.

-

MTTD and MTTR should decrease quarterly.

-

Closing time for high-risk findings should remain under 30 days.

-

The number of “major” findings in the audit should approach zero.

If you need a reference source that summarizes the scope of the standard family, this page is useful for a practical summary: IEC 62443 overview and sections.

Benefit: Compliance is assured, supply chain expectations are met, and OT security investments prove measurable results.

These five steps consolidate IEC 62443 implementation on a practical line. When risk assessment, network segmentation, firewall policies, access control, continuous monitoring, and certification come together, PLC security and SCADA security are concretely strengthened. Certification documents maturity and supports business continuity.

Avoid Common Mistakes and Increase Success

IEC 62443 provides a clear framework for OT security. Nevertheless, the same mistakes are repeated in the field. If you identify the following pitfalls early, your PLC security and SCADA security investments will yield results faster. Our focus is on network segmentation and firewall errors and their simple solutions.

Common Pitfalls and Solutions

Network segmentation errors increase the attack surface and facilitate spread. The most common ones and simple solutions:

-

Different risk levels in the same VLAN: Production cells, engineering stations, and SCADA servers are grouped in a single broadcast domain.

-

Solution: Apply the zone and conduit approach, define cell-based VLANs, and separate the IT-OT bridge with a DMZ.

-

-

Broad scope allow rules: “Any-to-any” or large IP ranges are used.

-

Solution: Open only the necessary source, destination, and port. Keep the default set to “deny”.

-

-

Failure to validate OT protocols: Modbus/TCP or DNP3 traffic is not inspected at the application level.

-

Solution: Enable application-aware rules, limit write functions to off-hours maintenance windows.

-

Firewall misconfigurations are also common:

-

Mixing management traffic with data traffic: RDP, SSH, SNMP flows are in the same rules.

-

Solution: Manage the management plane with a separate rule set, and mandate Multi-Factor Authentication (MFA).

-

-

Logs being off or scattered: Incident analysis cannot be performed.

-

Solution: Send logs to a central SIEM, and conduct a weekly review.

-

Other common mistakes and practical measures:

-

Legacy software: Outdated firmware and SCADA services generate risk.

-

Solution: Plan a maintenance window, and apply patches first in a test cell.

-

-

Inadequate training: Operator and engineer awareness remains low.

-

Solution: Repeat short, role-based training quarterly, include social engineering scenarios.

-

-

Lack of auditing: Rules remain untouched for years.

-

Solution: Conduct a monthly rule review and a network audit twice a year.

-

The long-term gain is clear: the attack surface shrinks, downtime decreases, and certification preparation accelerates. When you discipline segmentation and firewall policies with IEC 62443, operational continuity strengthens, and generating evidence in audits becomes easier.

IEC 62443 offers a clear path for PLC security and SCADA security. This framework reduces OT security goals to concrete steps. When network segmentation, firewall policies, access control, monitoring, and certification come together, risk drops, and continuity increases.

Start today, set up a pilot application in a narrow production cell. Complete the inventory, restrict the most critical flows, and activate MFA and log collection. Then measure, improve, and file the evidence. This tempo accelerates the certification process and establishes a mature defense line.

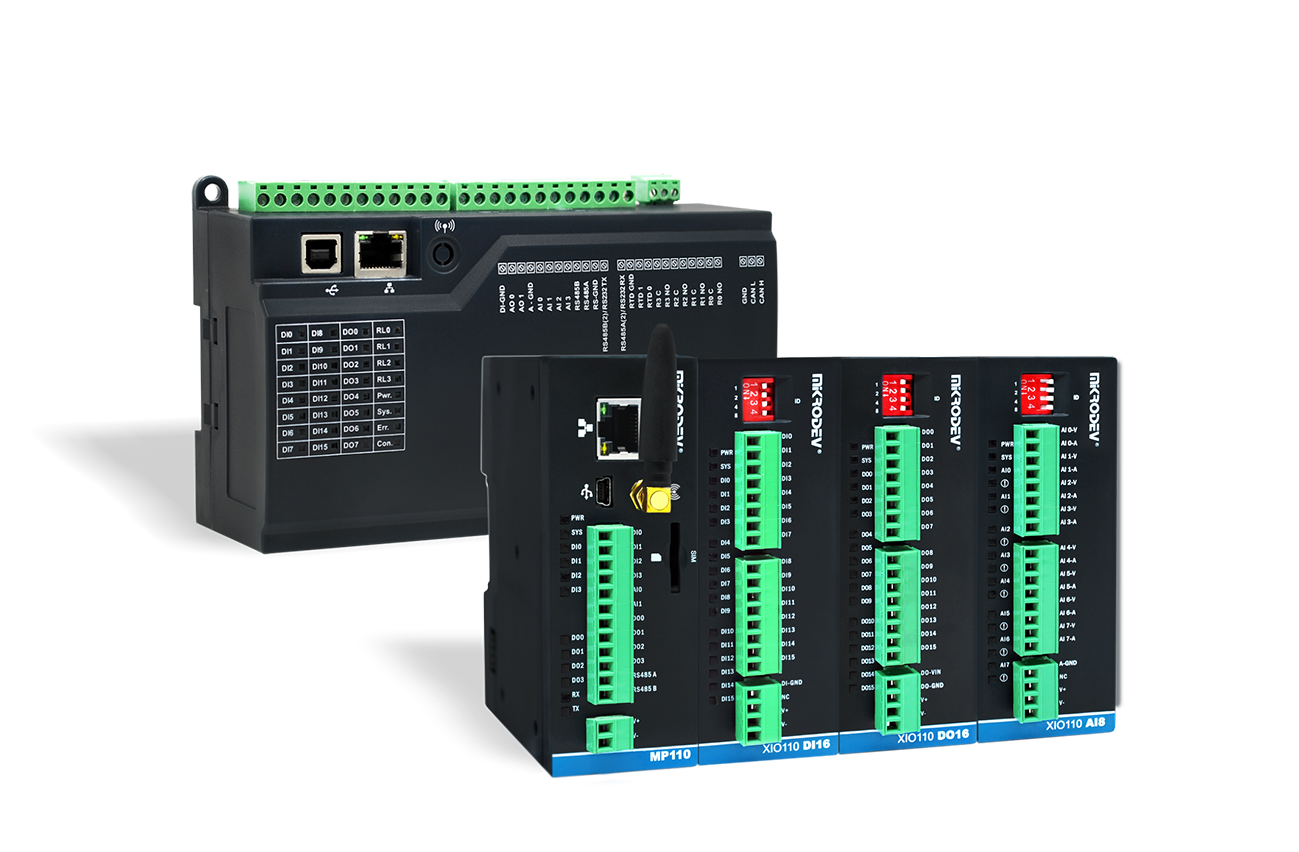

Preparation for future threats happens with regular patching, change management, and drills. Link IEC 62443 requirements to business processes, and review vendor access annually. Standardize secure configuration in PLC and SCADA components. Prioritize security in hardware selection, for example, review the Mikrodev PLC solutions page.

The summary is clear: with IEC 62443, OT security gains discipline, and the attack surface shrinks. PLC security and SCADA security investments produce measurable results, and the certification journey becomes more predictable. Take a step now, rapidly multiply small gains, and grow the operation with confidence.