In the dynamic landscape of modern manufacturing, efficiency and control are paramount. As industries evolve and technologies advance, staying ahead requires sophisticated solutions that optimize processes, reduce downtime, and ensure consistent quality. In this realm, Supervisory Control and Data Acquisition (SCADA) systems stand out as indispensable tools, offering a plethora of benefits to manufacturing operations.

What is SCADA?

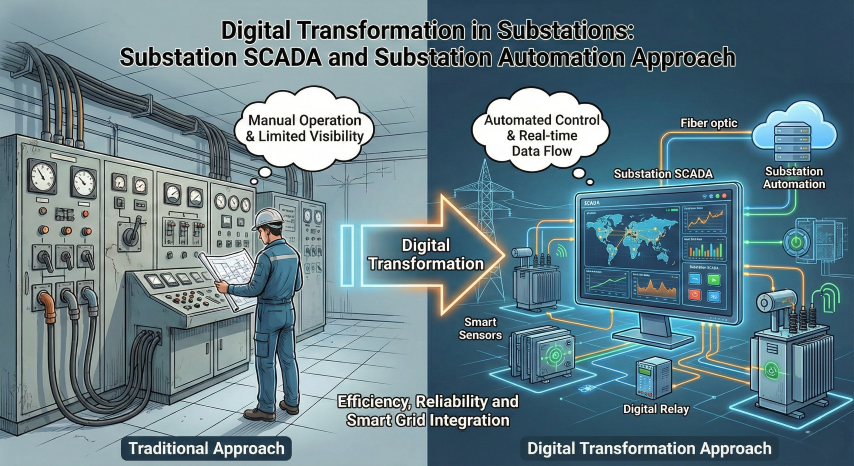

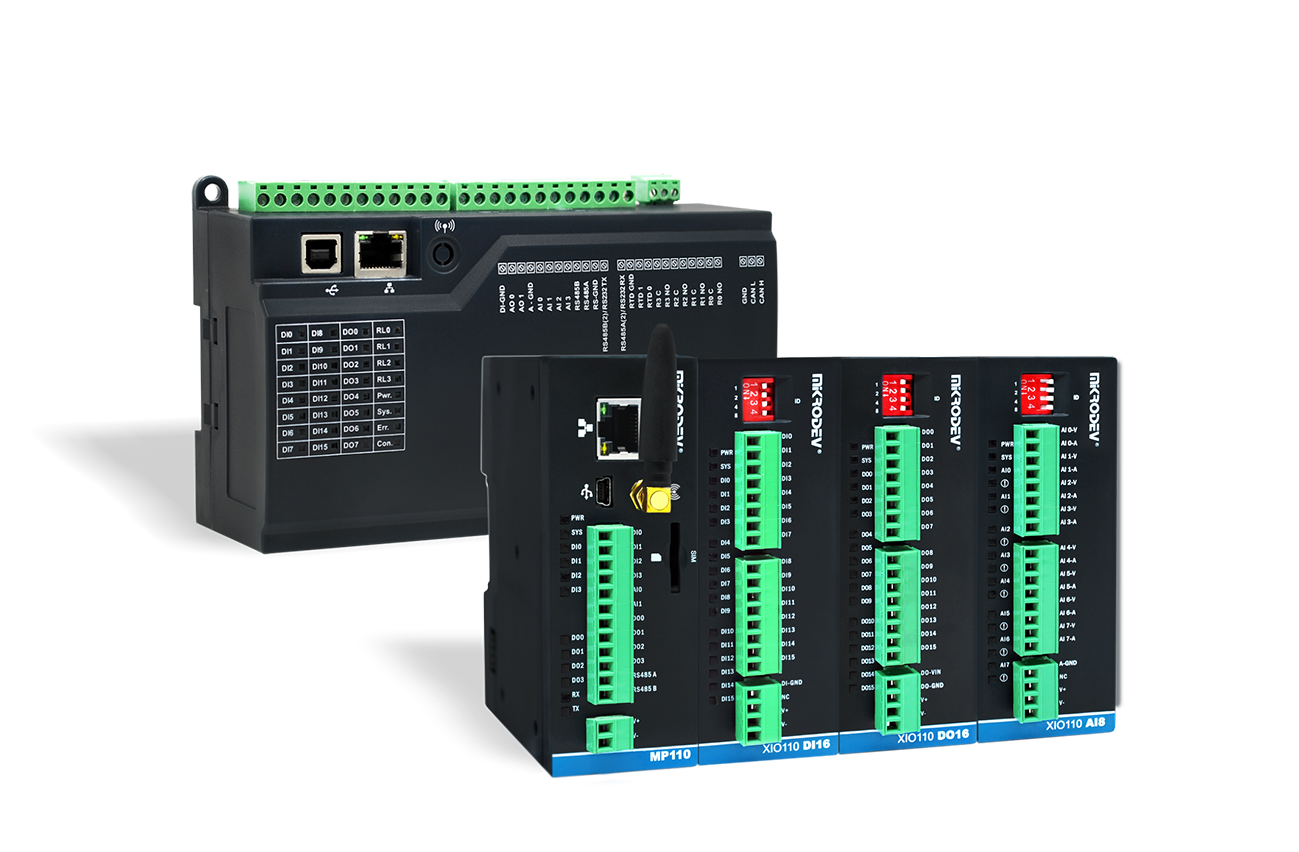

SCADA systems are comprehensive control solutions designed to monitor, gather, and process real-time data from various industrial processes. These systems provide operators with a centralized platform to visualize and analyze data, control processes remotely, and make informed decisions swiftly. SCADA encompasses hardware and software components working in tandem to manage complex industrial environments efficiently.

Learn more about SCADA: What is SCADA, Who Uses It and How It Works

SCADA Benefits in Manufacturing

1. Real-Time Monitoring and Control

SCADA systems provide real-time monitoring of industrial processes, allowing operators to stay informed about the status of equipment, production lines, and overall operations. This instantaneous visibility enables quick identification of issues, such as equipment failures or deviations from set parameters, empowering operators to take immediate corrective actions. By facilitating rapid responses, SCADA minimizes downtime and maximizes productivity, leading to significant cost savings.

2. Enhanced Efficiency and Productivity

With SCADA, manufacturing processes become more efficient and productive. By automating routine tasks and optimizing workflows, SCADA systems streamline operations, reduce manual interventions, and eliminate inefficiencies. Operators can remotely monitor multiple processes simultaneously, prioritize tasks based on real-time data, and make data-driven decisions to optimize resource utilization. The result is increased throughput, improved cycle times, and enhanced overall efficiency.

3. Improved Quality Control

Maintaining consistent product quality is essential for manufacturing success, and SCADA plays a crucial role in achieving this goal. SCADA systems continuously monitor key process parameters and perform real-time quality checks to ensure that products meet predefined specifications. Any deviations from quality standards trigger immediate alerts, allowing operators to intervene promptly and prevent defective products from reaching the market. By enforcing strict quality control measures, SCADA helps uphold brand reputation and customer satisfaction.

4. Remote Accessibility and Flexibility

SCADA systems offer remote accessibility, enabling operators to monitor and control manufacturing processes from anywhere with an internet connection. This remote capability provides unprecedented flexibility, allowing managers to oversee operations even when they are off-site or traveling. Whether it’s adjusting process parameters, troubleshooting equipment issues, or analyzing production data, operators can perform critical tasks remotely, thereby reducing response times and improving overall operational efficiency.

5. Data Analysis and Decision Support

SCADA systems generate vast amounts of data from various sensors and devices deployed across the manufacturing facility. This data is invaluable for performance analysis, trend identification, and decision-making. SCADA software provides powerful tools for data visualization, analytics, and reporting, enabling operators to gain actionable insights into process performance, equipment health, and energy consumption patterns. By harnessing the power of data, manufacturers can optimize processes, identify areas for improvement, and drive continuous innovation.

6. Scalability and Integration

As manufacturing operations evolve and expand, SCADA systems offer scalability and seamless integration with other technologies. Whether it’s integrating additional production lines, incorporating new sensors and devices, or connecting with enterprise systems such as ERP or MES, SCADA can adapt to changing requirements and grow alongside the business. This scalability ensures that manufacturers can leverage their existing investments in SCADA while embracing new technologies to drive innovation and competitiveness.

7. Regulatory Compliance and Safety

Compliance with industry regulations and safety standards is a top priority for manufacturing companies. SCADA systems support compliance efforts by providing comprehensive data logging, reporting, and audit trails. By maintaining accurate records of process parameters, equipment maintenance, and environmental conditions, SCADA helps manufacturers demonstrate regulatory compliance and respond effectively to audit requirements. Moreover, SCADA enhances safety in the workplace by monitoring critical parameters, detecting anomalies, and triggering alarms in case of emergencies, thereby minimizing risks to personnel and assets.

Conclusion

In the fast-paced world of manufacturing, staying competitive requires leveraging advanced technologies that enhance efficiency, control, and agility. SCADA systems emerge as indispensable tools, offering a myriad of benefits ranging from operational optimization and remote monitoring to data-driven insights and quality control. By embracing SCADA, manufacturers can navigate the complexities of modern industry with confidence, unlocking new opportunities for growth, innovation, and success.

These blogs might be interesting for you: